Field tests of CO2 huff-n-puff technology in Nanchuan normal-pressure shale gas field

-

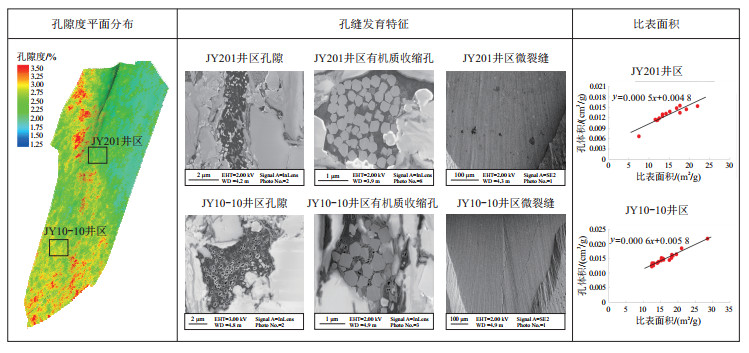

摘要: 受吸附态甲烷占比高、地层能量弱等影响,常压页岩气藏采收率普遍不足30%。中国石化率先在四川盆地南川常压页岩气田开展注CO2吞吐矿场试验,验证了海相页岩气注CO2提高采收率的可行性。为推广该技术,以南川常压页岩气田为研究对象,开展室内实验—数值模拟—吞吐动态分析全链条研究,分析CO2在不同页岩储层中竞争吸附差异性,探究矿场CO2注入、吞吐特征,明确页岩气注CO2吞吐提高采收率技术“增能+置换+解水锁”多机制协同机理,进而指导选井及方案优化。综合利用电镜扫描、测井解释、等温吸附实验等方法,揭示南川地区上奥陶统五峰组—下志留统龙马溪组常压页岩储层随埋深变浅、地层压力减小以及孔隙度、TOC和黏土矿物含量的增加,CO2竞争吸附能力增强,超临界态CO2吸附量最高可达CH4的6~7倍。现场页岩气井注CO2吞吐后,日产气可提高3.5~6.5倍,采收率提升1.9%~3.1%。根据2井3轮次注入—焖井阶段压力监测,CO2主要集中在近井地带微裂缝中,扩散距离与地层压力、压裂缝网导流能力有关,一般不超过70 m。CO2吞吐可划分为初期CO2快速返排、早期提产和中后期稳产3个阶段,增产机理分别为早期增能补能、中期膨胀助排+解水锁、后期吸附置换+分压促解吸。吞吐提产的主要影响因素为储层改造程度和采出程度。中深层压裂效果较差的井在吞吐中早期换气率高,浅层采出程度较高的井在吞吐中后期累增气量高。结合数值模拟,建议优选吸附能力强、采出程度20%~30%、携液能力较差且关井压力尽可能达到7 MPa的井开展矿场先导试验。在低压低产阶段,中深层井可开展小规模多轮次注CO2吞吐以增能助排,浅层井可开展大规模注CO2吞吐以补充地层能量、吸附置换实现采收率提升。Abstract: Due to the high proportion of adsorbed methane and weak formation energy, the recovery rate of normal-pressure shale gas reservoirs is generally less than 30%. SINOPEC took the lead in conducting CO2 huff-n-puff field tests in the Nanchuan normal-pressure shale gas field in the Sichuan Basin, verifying the feasibility of CO2 injection for enhanced recovery of marine shale gas. To promote this technology, a comprehensive study was carried out on the Nanchuan normal-pressure shale gas field, involving laboratory experiments, numerical simulations, and dynamic huff-n-puff analysis. The study analyzed the CO2 competitive adsorption differences in different shale reservoirs, explored the CO2 huff-n-puff characteristics in the field, and clarified the synergistic effects of CO2 huff-n-puff to enhance shale gas recovery (ESGR) technology through multi-mechanisms of energy enhancement, displacement, and water-unlocking, aiming to guide well selection and program optimization. Using techniques such as electron microscope scanning, well logging interpretation, and isothermal adsorption experiments, the study revealed that the CO2 competitive adsorption capacity of normal-pressure shale reservoirs in the Upper Ordovician Wufeng and the Lower Silurian Longmaxi formations of the Nanchuan area increased with decreased burial depth and formation pressure, and with increased porosity, TOC, and clay mineral content. The adsorption capacity of supercritical CO2 was found to be 6 to 7 times higher than that of CH4. After CO2 huff-n-puff operations in shale gas wells, the daily gas production increased by 3.5 to 6.5 times, and the recovery rate increased by 1.9% to 3.1%. Based on pressure monitoring during the injection and soaking stages of two wells over three rounds of CO2 injection, CO2 mainly concentrated in the near-well micro-fractures. The diffusion distance, generally not exceeding 70 m, was related to formation pressure and the conductivity of fracture network. The process of CO2 huff-n-puff can be divided into three stages: early rapid CO2 flowback, early production increase, and mid- to late-stage stable production. The production increase mechanisms include early energy enhancement and supplementation, mid-stage expansion and expulsion assistance + water lock removal, and late-stage adsorption displacement + desorption promotion by partial pressure. The main influencing factors for increased huff-n-puff production are the degree of reservoir modification and recovery. Wells with poor fracturing effects in medium and deep layers had a higher gas exchange rate during the early and middle stages of CO2 huff-n-puff, while wells with high recovery rates in shallow layers had a higher cumulative gas increase in the middle and late stages. Based on numerical simulations, it is recommended to prioritize wells with strong adsorption capacity, a recovery rate of 20% to 30%, poor liquid carrying capacity, and a shut-in pressure as close to 7 MPa as possible for field pilot tests. In the low-pressure and low-yield stage, small-scale multiple rounds of CO2 huff-n-puff can be carried out in medium-deep wells for energy enhancement and expulsion assistance, while large-scale CO2 huff-n-puff can be conducted in shallow wells to replenish formation energy and achieve enhanced recovery through adsorption displacement.

-

Key words:

- normal-pressure shale gas /

- CO2 huff-n-puff /

- field test /

- recovery rate /

- well selection /

- Sichuan Basin

-

表 1 南川气田试验井注CO2前后压力变化

Table 1. Pressure changes before and after CO2 injection in test wells of Nanchuan gas field

井号(轮次) 注气前 裂缝半长/m CO2注入量/t 注入压力/MPa 焖井阶段 扩散距离/m 采出程度/% 地层压力/MPa 套压/MPa 平衡时间/d 套压/MPa 井底压力/MPa JY201-3HF(第1轮) 18.3 27.6 1.18 89 708.3 11.0 10 9.8 12.8 20 JY201-3HF(第2轮) 21.7 23.8 1.20 89 1 307.7 8.9 15 8.0 10.0 35 JY10-10HF(第1轮) 26.2 12.5 0.70 113 2 009.8 3.8 2 3.4 4.2 70 表 2 南川气田试验井注CO2前后生产指标对比

Table 2. Comparison of production indicators before and after CO2 injection in test wells of Nanchuan gas field

井号(轮次) 吞吐前 吞吐后 套压/MPa 日产气/104 m3 累产气/104 m3 套压/MPa 日产气/104m3 累产气/104 m3 累增气/104 m3 JY201-3HF(第1轮) 1.18 0.96 3 006 5.8 3.3 359 116 JY201-3HF(第2轮) 1.20 1.02 3 429 5.6 4.2 336 195 JY10-10HF(第1轮) 0.70 0.90 4 375 2.7 5.8 615 278 表 3 常压页岩气井注CO2吞吐选井评价指标

Table 3. Well selection evaluation criteria for CO2 huff-n-puff operations in normal-pressure shale gas wells

评价原则 评价指标 适用范围 可注入性 孔隙度/% ≥3.5 渗透率/10-3 μm2 ≥2×10-4 压裂改造效果 效果好,裂缝半长大于100 m 可增产性 吸附气 含量大于2.5 m3/t,或占比大于30% 生产特征 初产高、递减快、低产期长,或存在应力敏感现象 最佳注入阶段 低压低产,采出程度介于20%~30%之间 可封存性 顶底板岩性 致密,有效盖层厚度大于10 m 压裂对盖层影响 无 断层发育水平 开启性断层不发育或断层封闭 裂缝发育情况 压裂沟通天然裂缝,形成大型、复杂缝网系统 最佳注入阶段 生产末期,采出程度大于70% -

[1] 蔡勋育, 周德华, 赵培荣, 等. 中国石化深层、常压页岩气勘探开发进展与展望[J]. 石油实验地质, 2023, 45(6): 1039-1049. doi: 10.11781/sysydz2023061039CAI Xunyu, ZHOU Dehua, ZHAO Peirong, et al. Development progress and outlook of deep and normal pressure shale gas of SINOPEC[J]. Petroleum Geology & Experiment, 2023, 45(6): 1039-1049. doi: 10.11781/sysydz2023061039 [2] 张培先, 聂海宽, 何希鹏, 等. 渝东南地区古生界天然气成藏体系及立体勘探[J]. 地球科学, 2023, 48(1): 206-222.ZHANG Peixian, NIE Haikuan, HE Xipeng, et al. Paleozoic gas accumulation system and stereoscopic exploration in southeastern Chongqing[J]. Earth Science, 2023, 48(1): 206-222. [3] 姚红生, 王伟, 何希鹏, 等. 南川复杂构造带常压页岩气地质工程一体化开发实践[J]. 油气藏评价与开发, 2023, 13(5): 537-547.YAO Hongsheng, WANG Wei, HE Xipeng, et al. Development practices of geology-engineering integration in complex structural area of Nanchuan normal pressure shale gas field[J]. Petroleum Reservoir Evaluation and Development, 2023, 13(5): 537-547. [4] 周德华, 何希鹏, 张培先. 渝东南常压与高压页岩气典型差异性分析及效益开发对策[J]. 石油实验地质, 2023, 45(6): 1109-1120. doi: 10.11781/sysydz2023061109ZHOU Dehua, HE Xipeng, ZHANG Peixian. Typical difference analysis and benefit-oriented development countermeasures of normal and high pressure shale gas in southeastern Chongqing[J]. Petroleum Geology & Experiment, 2023, 45(6): 1109-1120. doi: 10.11781/sysydz2023061109 [5] 何希鹏, 张培先, 任建华, 等. 渝东南南川地区东胜构造带常压页岩气勘探开发实践[J]. 石油实验地质, 2023, 45(6): 1057-1066. doi: 10.11781/sysydz2023061057HE Xipeng, ZHANG Peixian, REN Jianhua, et al. Exploration and development practice of normal pressure shale gas in Dongsheng structural belt, Nanchuan area, southeast Chongqing[J]. Petroleum Geology & Experiment, 2023, 45(6): 1057-1066. doi: 10.11781/sysydz2023061057 [6] 王光付, 李凤霞, 王海波, 等. 四川盆地不同类型页岩气压裂难点和对策[J]. 石油与天然气地质, 2023, 44(6): 1378-1392.WANG Guangfu, LI Fengxia, WANG Haibo, et al. Difficulties and countermeasures for fracturing of various shale gas reservoirs in the Sichuan Basin[J]. Oil & Gas Geology, 2023, 44(6): 1378-1392. [7] 王纪伟, 宋丽阳, 康玉柱, 等. 中美典型常压页岩气开发对比与启示[J]. 特种油气藏, 2024, 31(4): 1-9.WANG Jiwei, SONG Liyang, KANG Yuzhu, et al. Comparison and implications of typical normal pressure shale gas development between China and the United States[J]. Special Oil & Gas Reservoirs, 2024, 31(4): 1-9. [8] 邓佳, 吕子健, 张奇, 等. 页岩储层纳微米孔隙CO2/CH4吸附及驱替特性研究进展[J]. 力学学报, 2021, 53(10): 2880-2890.DENG Jia, LÜ Zijian, ZHANG Qi, et al. Review on CO2/CH4 adsorption and displacement characteristics of micro-nano pores in shale reservoir[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(10): 2880-2890. [9] KLEWIAH I, BERAWALA D S, WALKER H C A, et al. Review of experimental sorption studies of CO2 and CH4 in shales[J]. Journal of Natural Gas Science and Engineering, 2020, 73: 103045. [10] SUN Ying, LI Shuxia, SUN Renyuan, et al. Study of CO2 enhancing shale gas recovery based on competitive adsorption theory[J]. ACS Omega, 2020, 5(36): 23429-23436. doi: 10.1021/acsomega.0c03383 [11] 郑永旺, 崔轶男, 李鑫, 等. 深层高阶煤层CO2-ECBM技术研究与应用启示: 以沁水盆地晋中地区为例[J]. 石油实验地质, 2025, 47(1): 143-152. doi: 10.11781/sysydz2025010143ZHENG Yongwang, CUI Yinan, LI Xin, et al. Research and insights for application of CO2-ECBM technology in deep high-rank coal seams: a case study of Jinzhong block, Qinshui Basin[J]. Petroleum Geology & Experiment, 2025, 47(1): 143-152. doi: 10.11781/sysydz2025010143 [12] 贾连超, 刘鹏飞, 袁丹, 等. 注CO2提高页岩吸附气采收率实验: 以鄂尔多斯盆地延长组长7页岩气为例[J]. 大庆石油地质与开发, 2021, 40(2): 153-159.JIA Lianchao, LIU Pengfei, YUAN Dan, et al. Experiment of enhancing the recovery of the shale adsorbed gas by CO2 injection: taking Yanchang-Formation Chang-7 shale gas in Ordos Basin as an example[J]. Petroleum Geology & Oilfield Development in Daqing, 2021, 40(2): 153-159. [13] 张添锦, 王延峰, 李军, 等. 注CO2提高页岩吸附甲烷采收率核磁共振实验[J]. 特种油气藏, 2023, 30(5): 113-120.ZHANG Tianjin, WANG Yanfeng, LI Jun, et al. Nuclear magnetic resonance experiment for enhanced recovery of adsorbed methane from shale through carbon dioxide injection[J]. Special Oil & Gas Reservoirs, 2023, 30(5): 113-120. [14] WANG Yingnan, JIN Zhehui. Hydrocarbon mixture and CO2 adsorptions in a nanopore-bulk multiscale system in relation to CO2 enhanced shale gas recovery[J]. Chemical Engineering Journal, 2021, 415: 128398. doi: 10.1016/j.cej.2020.128398 [15] 周宇, 孙乾, 张娜, 等. 页岩油-CO2、CH4、N2混合物界面性质的分子动力学模拟研究[J]. 油气地质与采收率, 2024, 31(6): 109-117.ZHOU Yu, SUN Qian, ZHANG Na, et al. Molecular dynamics simulations of interfacial properties of shale oil-CO2, CH4, N2 mixtures[J]. Petroleum Geology and Recovery Efficiency, 2024, 31(6): 109-117. [16] 赵玉龙, 黄义书, 张涛, 等. 页岩气藏超临界CO2压裂—提采—封存研究进展[J]. 天然气工业, 2023, 43(11): 109-119.ZHAO Yulong, HUANG Yishu, ZHANG Tao, et al. Research progress on supercritical CO2 fracturing, enhanced gas recovery and storage in shale gas reservoirs[J]. Natural Gas Industry, 2023, 43(11): 109-119. [17] MANSI M, ALMOBARAK M, LAGAT C, et al. Statistical analysis of controlling factors on enhanced gas recovery by CO2 injection in shale gas reservoirs[J]. Energy & Fuels, 2023, 37(2): 965-976. [18] QIN Chao, JIANG Yongdong, CAO Mengyao, et al. Experimental study on the methane desorption-diffusion behavior of Longmaxi shale exposure to supercritical CO2[J]. Energy, 2023, 262: 125456. doi: 10.1016/j.energy.2022.125456 [19] 刘军. 四川盆地页岩储层初步评价及注CO2提高采收率潜力评价[D]. 北京: 中国地质大学(北京), 2018.LIU Jun. Preliminary evaluation on shales in Sichuan Basin and potential for enhancing gas recovery by CO2 injection[D]. Beijing: China University of Geosciences (Beijing), 2018. [20] KELES C, TANG X, SCHLOSSER C, et al. Sensitivity and history match analysis of a carbon dioxide 'huff-and-puff' injection test in a horizontal shale gas well in Tennessee[J]. Journal of Natural Gas Science and Engineering, 2020, 77: 103226. doi: 10.1016/j.jngse.2020.103226 [21] YU Wei, AL-SHALABI E W, SEPEHRNOORI K. A sensitivity study of potential CO2 injection for enhanced gas recovery in Barnett shale reservoirs[C]//SPE Unconventional Resources Conference. The Woodlands: SPE, 2014: SPE-169012-MS. [22] PRASAD S K, SANGWAI J S, BYUN H S. A review of the supercritical CO2 fluid applications for improved oil and gas production and associated carbon storage[J]. Journal of CO2 Utilization, 2023, 72: 102479. doi: 10.1016/j.jcou.2023.102479 [23] WANG Dong, LI Yongming, WANG Bo, et al. Re-fracturing vs. CO2 huff-n-puff injection in a tight shale reservoir for enhancing gas production[J]. Frontiers in Energy Research, 2023, 10: 922860. doi: 10.3389/fenrg.2022.922860 [24] NUTTALL B C, EBLE C F, DRAHOVZAL J A, et al. Analysis of Devonian black shales in Kentucky for potential carbon dioxide sequestration and enhanced natural gas production[R]. Amsterdam: Elsevier Science Ltd, 2005. [25] LOUK K, RIPEPI N, LUXBACHER K, et al. Monitoring CO2 storage and enhanced gas recovery in unconventional shale reservoirs: results from the Morgan County, Tennessee injection test[J]. Journal of Natural Gas Science and Engineering, 2017, 45: 11-25. [26] 姚红生, 房大志, 卢义玉, 等. 南川常压海相页岩气注CO2吞吐提高采收率工程实践[J]. 天然气工业, 2024, 44(4): 83-92.YAO Hongsheng, FANG Dazhi, LU Yiyu, et al. Engineering practice of CO2 ESGR in Nanchuan normal-pressure marine shale gas reservoirs[J]. Natural Gas Industry, 2024, 44(4): 83-92. [27] 倪锋, 朱峰, 孟庆利. 渝东南地区南川区块膝折构造模式解析[J]. 油气藏评价与开发, 2024, 14(3): 373-381.NI Feng, ZHU Feng, MENG Qingli. Analysis of knee fold structure model in Nanchuan block of southeastern Chongqing[J]. Petroleum Reservoir Evaluation and Development, 2024, 14(3): 373-381. [28] 张培先, 高全芳, 何希鹏, 等. 南川地区龙马溪组页岩气地应力场特征及对产量影响分析[J]. 油气地质与采收率, 2023, 30(4): 55-65.ZHANG Peixian, GAO Quanfang, HE Xipeng, et al. Characteristics of in-situ stress field and its influence on shale gas production from Longmaxi Formation in Nanchuan area[J]. Petroleum Geology and Recovery Efficiency, 2023, 30(4): 55-65. [29] 云露. 四川盆地东南缘浅层常压页岩气聚集特征与勘探启示[J]. 石油勘探与开发, 2023, 50(6): 1140-1149.YUN Lu. Accumulation characteristics and exploration enlightenment of shallow normal-pressure shale gas in southeastern Sichuan Basin, SW China[J]. Petroleum Exploration and Development, 2023, 50(6): 1140-1149. [30] 侯大力, 韩鑫, 唐洪明, 等. 龙马溪组页岩干酪根表征初探及干酪根吸附特征研究[J]. 油气藏评价与开发, 2023, 13(5): 636-646.HOU Dali, HAN Xin, TANG Hongming, et al. Primary research on expression of kerogen in Longmaxi shale and its adsorption characteristics[J]. Petroleum Reservoir Evaluation and Development, 2023, 13(5): 636-646. [31] 汤勇, 胡世莱, 汪勇, 等. "注入—压裂—返排"全过程的CO2相态特征: 以鄂尔多斯盆地神木气田致密砂岩气藏SH52井为例[J]. 天然气工业, 2019, 39(9): 58-64.TANG Yong, HU Shilai, WANG Yong, et al. Phase behaviors of CO2 in the whole process of injection-fracturing-flowback: a case study of well SH52 in a fight sandstone gas reservoir of the Shenmu Gas Field, Ordos Basin[J]. Natural Gas Industry, 2019, 39(9): 58-64. [32] 卓亭妤. 二氧化碳在页岩上的吸附动力学及驱替页岩气的研究[D]. 重庆: 重庆大学, 2020.ZHUO Tingyu. Study on adsorption kinetics of carbon dioxide on shale and the shale gas displacement by carbon dioxide[D]. Chonqing: Chongqing University, 2020. [33] 朱维耀, 沙玉博, 孔德彬, 等. 深层致密气藏气体扩散渗流数学模型及影响因素[J]. 天然气地球科学, 2021, 32(5): 695-702.ZHU Weiyao, SHA Yubo, KONG Debin, et al. Mathematical diffusion-filtration model of gas in deep and tight gas reservoir and analysis of influencing factors[J]. Natural Gas Geoscience, 2021, 32(5): 695-702. [34] 商慧敏. 页岩气藏注CO2提高采收率可行性实验研究[D]. 青岛: 中国石油大学(华东), 2017.SHANG Huimin. Feasibility experimental studies of potential CO2 injection for enhanced gas recovery in shale gas reservoirs[D]. Qingdao: China University of Petroleum (East China), 2017. [35] 张莉娜, 任建华, 胡春锋. 常压页岩气立体开发特征及缝网干扰规律研究[J]. 石油钻探技术, 2023, 51(5): 149-155.ZHANG Lina, REN Jianhua, HU Chunfeng. Three-dimensional development characteristics and fracture network interference of atmospheric shale gas reservoir[J]. Petroleum Drilling Techniques, 2023, 51(5): 149-155. [36] 张志超, 柏明星, 杜思宇. 页岩油藏注CO2驱孔隙动用特征研究[J]. 油气藏评价与开发, 2024, 14(1): 42-47.ZHANG Zhichao, BAI Mingxing, DU Siyu. Characteristics of pore dynamics in shale reservoirs by CO2 flooding[J]. Petroleum Reservoir Evaluation and Development, 2024, 14(1): 42-47. [37] KUANG Nianjie, ZHOU Junping, TIAN Shifeng, et al. Fluid-solid coupling model with the multiple flow mechanism for CO2-enhanced shale gas recovery and CO2 sequestration[J]. Energy & Fuels, 2024, 38(8): 7068-7084. [38] 王志坚. CO2相态变化致裂对煤层吸附性影响机理研究[J]. 油气藏评价与开发, 2024, 14(6): 967-974.WANG Zhijian. Mechanism study on effect of CO2 phase transition fracturing on methane adsorption in coal[J]. Petroleum Reservoir Evaluation and Development, 2024, 14(6): 967-974. [39] 周敏琪. 页岩气注CO2吞吐的研究[D]. 重庆: 重庆大学, 2021.ZHOU Minqi. Research on huff and puff of shale gas CO2 injection[D]. Chonqing: Chongqing University, 2021. [40] ZHAO Peng, XIE Lingzhi, HE Bo, et al. Anisotropic permeability influencing the performance of free CH4 and free CO2 during the process of CO2 sequestration and enhanced gas recovery (CS-EGR) from shale[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(2): 914-926. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号