Microscopic characteristics of sulfur depositions in high-sulfur-content reservoirs

-

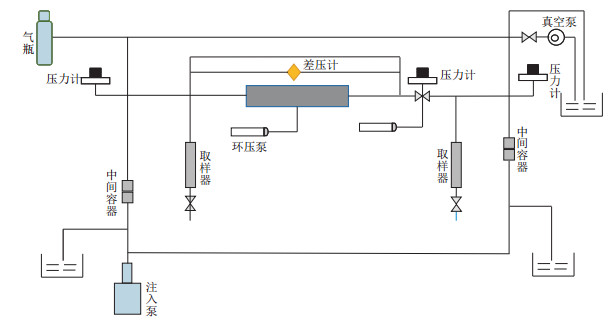

摘要: 四川盆地川东北地区相继发现了一大批高含硫碳酸盐岩气藏,其储量占四川盆地天然气储量的一半以上。然而,硫沉积一直是制约高含硫气藏高效开发的一大难题。结合微米CT扫描、扫描电镜、能谱分析和气相色谱分析等实验手段,运用储层高含硫气体完成了碳酸盐岩岩样的硫沉积实验,获得了实验前后岩样微观孔隙结构和气体组分的定量变化,首次实现了储层岩石中硫沉积的三维可视化。硫沉积实验结果显示,高含硫气体中总硫含量减小12.58%,有机硫组分减小9.07%;硫微粒主要沉积在半径小于500μm的岩石孔隙中,导致岩石渗透率降低34.40%~67.80%,孔隙度减小3.77%~7.69%。研究结果进一步提升了对硫沉积微观特性的认识,为高含硫气藏增产措施的制定提供了支撑。Abstract: A large number of high-sulfur-content carbonate gas reservoirs have been discovered in the northeastern part of the Sichuan Basin, and their reserve accounts for more than half of the total natural gas reserves in the basin. However, sulfur deposition has been a major problem for a long period which is restricting for the efficient development of high-sulfur-content gas reservoirs. In this paper, sulfur deposition experiments in carbonate rock samples were carried out with high-sulfur-content natural gas by the means of micro-CT scanning, scanning electron microscopy, gas chromatograph and energy spectrum analysis. The changes of the microscopic pore structure of the samples and gas composition before and after the experiments were quantitatively obtained, and the 3D visualization of sulfur deposition in reservoir rocks was achieved for the first time. Results show that after sulfur deposition experiment, the total sulfur content in high-sulfur-content gas decreased by 12.58%, and the organic sulfur component decreased by 9.07%. Sulfur particles were mainly deposited in rock pores with a radius of less than 500 μm, resulting in decreases in rock permeability and porosity by 34.40%-67.80% and 3.77%-7.69%, respectively. This study further improved the understanding of the microscopic characteristics of sulfur deposition and provided support for the formulation of production enhancement measures for high-sulfur-content gas reservoirs.

-

表 1 硫沉积实验岩样的基础物性

Table 1. Basic physical properties of core samples for sulfur deposition experiment

岩样 直径/mm 长度/mm 孔隙度/% 渗透率/10-3 μm2 孔隙类型 18-2 25.2 28.0 5.45 0.014 孔洞 19-3 25.1 40.1 4.17 0.380 裂缝洞 表 2 实验前后实验气体的组分分析结果

Table 2. Gas component before and after sulfur deposition experiment

气体组分 实验前含量/(mg·m-3) 实验后含量/(mg·m-3) 相对变化率/% COS 67.67 61.88 -8.56 CS2 0.57 13.46 2 222.53 CH4S 19.48 7.59 -61.08 C2H6S 4.67 1.47 -68.52 C3H8S 0.39 0 -100.00 -

[1] 李阳, 康志江, 薛兆杰, 等. 中国碳酸盐岩油气藏开发理论与实践[J]. 石油勘探与开发, 2018, 45(4): 669-678. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201804013.htmLI Yang, KANG Zhijiang, XUE Zhaojie, et al. Theories and practices of carbonate reservoirs development in China[J]. Petroleum Exploration and Development, 2018, 45(4): 669-678. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201804013.htm [2] 廖荣峰, 汤晶, 宋晓波, 等. 川西南下三叠统嘉陵江组四-五段孔隙型储层特征及勘探前景[J]. 石油实验地质, 2022, 44(1): 60-70. doi: 10.11781/sysydz202201060LIAO Rongfeng, TANG Jing, SONG Xiaobo, et al. Characteristics and exploration potential of porous reservoirs in 4th to 5th members of Lower Triassic Jialingjiang Formation in southwestern Sichuan Basin[J]. Petroleum Geology & Experiment, 2022, 44(1): 60-70. doi: 10.11781/sysydz202201060 [3] 丁康乐, 李术元, 岳长涛, 等. 碳酸盐岩储集层含H2S天然气成因研究[J]. 新疆石油地质, 2008, 29(4): 535-538. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200804043.htmDING Kangle, LI Shuyuan, YUE Changtao, et al. Study on the genesis of H2S-bearing natural gas in carbonate reservoirs[J]. Xinjiang Petroleum Geology, 2008, 29(4): 535-538. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200804043.htm [4] 石书缘, 胡素云, 汪泽成, 等. 四川盆地寒武系洗象池组滩相白云岩规模储层发育特征及勘探意义[J]. 石油实验地质, 2022, 44(3): 433-447. doi: 10.11781/sysydz202203433SHI Shuyuan, HU Suyun, WANG Zhecheng, et al. Characteristics and exploration prospect of dolograinstone beach reservoir in Xixiangchi Formation, Cambrian, Sichuan Basin[J]. Petroleum Geology & Experiment, 2022, 44(3): 433-447. doi: 10.11781/sysydz202203433 [5] 李宁, 王克文, 张宫, 等. 应用CT分析及核磁测井预测碳酸盐岩产气量[J]. 石油勘探与开发, 2015, 42(2): 150-157. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201502004.htmLI Ning, WANG Kewen, ZHANG Gong, et al. Prediction of gas production in carbonates based on CT analysis and nuclear magnetic resonance (NMR) logging[J]. Petroleum Exploration and Development, 2015, 42(2): 150-157. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201502004.htm [6] MACHEL H G. Gas souring by thermochemical sulfate reduction at 140℃: discussion[J]. AAPG Bulletin, 1998, 82(10): 1870-1873. http://www.researchgate.net/publication/299016210_Gas_souring_by_thermochemical_sulfate_reduction_at_140_degrees_C_Discussion [7] 刘文汇, 腾格尔, 高波, 等. 四川盆地大中型天然气田(藏)中H2S形成及富集机制[J]. 石油勘探与开发, 2010, 37(5): 513-522. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201005001.htmLIU Wenhui, TENGGER, GAO Bo, et al. H2S formation and enrichment mechanism in medium to large scale natural gas fields (reservoirs) in Sichuan Basin[J]. Petroleum Exploration and Development, 2010, 37(5): 513-522. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201005001.htm [8] 戴金星, 倪云燕, 秦胜飞, 等. 四川盆地超深层天然气地球化学特征[J]. 石油勘探与开发, 2018, 45(4): 588-597. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201804006.htmDAI Jinxing, NI Yunyan, QIN Shengfei, et al. Geochemical characte-ristics of ultra-deep natural gas in the Sichuan Basin, SW China[J]. Petroleum Exploration and Development, 2018, 45(4): 588-597. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201804006.htm [9] 王丽, 周克明, 张地洪, 等. 高含硫气藏水合物形成机理的实验研究[J]. 天然气工业, 2003, 23(3): 97-100. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG200303034.htmWANG Li, ZHOU Keming, ZHANG Dihong, et al. Experimental investigation of hydrate forming mechanism in gas reservoirs with high sulfur content[J]. Natural Gas Industry, 2003, 23(3): 97-100. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG200303034.htm [10] 朱光有, 张水昌, 李剑, 等. 中国高含硫化氢天然气的形成及其分布[J]. 石油勘探与开发, 2004, 31(3): 18-21. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK200403004.htmZHU Guangyou, ZHANG Shuichang, LI Jian, et al. Formation and distribution of hydrogen sulfide bearing gas in China[J]. Petroleum Exploration and Development, 2004, 31(3): 18-21. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK200403004.htm [11] HU Jinghong, YANG Xuefeng, HE Shunli, et al. Distribution of sulfur deposition near a wellbore in a sour gas reservoir[J]. Journal of Geophysics and Engineering, 2013, 10(1): 015005. http://www.onacademic.com/detail/journal_1000037437240310_aae5.html [12] GUO Xiao, WANG Qiao. A new prediction model of elemental sulfur solubility in sour gas mixtures[J]. Journal of Natural Gas Science and Engineering, 2016, 31: 98-107. http://www.researchgate.net/profile/Jing_Hong_Hu/publication/260214713_Prediction_model_of_elemental_sulfur_solubility_in_sour_gas_mixtures/links/5490df650cf2d1800d87c2a9.pdf [13] ROBERTS B E. The effect of sulfur deposition on gas well inflow performance[J]. SPE Reservoir Engineering, 1997, 12(2): 118-123. http://www.researchgate.net/publication/239436113_The_Effect_of_Sulfur_Deposition_on_Gaswell_Inflow_Performance [14] 张勇, 杜志敏, 王强, 等. 硫微粒在多孔介质中运移沉积模型[J]. 新疆石油地质, 2009, 30(5): 606-608. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200905023.htmZHANG Yong, DU Zhimin, WANG Qiang, et al. The model for sulfur particle flow and deposition in porous medium[J]. Xinjiang Petroleum Geology, 2009, 30(5): 606-608. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200905023.htm [15] MAHMOUD M A A. Effect of elemental-sulfur deposition on the rock petrophysical properties in sour-gas reservoirs[J]. SPE Journal, 2014, 19(4): 703-715. http://www.onacademic.com/detail/journal_1000039105702710_3ebf.html [16] 张勇, 杜志敏, 郭肖, 等. 硫沉积对高含硫气藏产能影响数值模拟研究[J]. 天然气工业, 2007, 27(6): 94-96. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG200706028.htmZHANG Yong, DU Zhimin, GUO Xiao, et al. A numerical simulation study on the impact of sulfur deposit on productivity of sour gas reservoirs[J]. Natural Gas Industry, 2007, 27(6): 94-96. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG200706028.htm [17] ADESINA F, CHURCHILL A. Prediction of elemental sulphur saturation around the wellbore[J]. Global Journal of Researches in Engineering, 2010, 10(2): 31-37. http://www.researchgate.net/profile/Adesina_Fadairo2/publication/265289674_Prediction_of_Elemental_Sulphur_Saturation_around_the_Wellbore/links/55430c5d0cf23ff716837b1f/Prediction-of-Elemental-Sulphur-Saturation-around-the-Wellbore.pdf [18] HU Jinghong, HE Shunli, ZHAO Jinzhou, et al. Modeling of sulfur plugging in a sour gas reservoir[J]. Journal of Natural Gas Science and Engineering, 2013, 11: 18-22. http://www.cugb.edu.cn/upload/20600/papers_upload/225.pdf [19] KUO C H, CLOSMANN P J. Theoretical study of fluid flow accompanied by solid precipitation in porous media[J]. AIChE Journal, 1966, 12(5): 995-998. http://www.onacademic.com/detail/journal_1000033738585710_7ee3.html [20] 郭珍珍, 李治平, 赖枫鹏, 等. 考虑硫沉积的气井流入动态曲线特征[J]. 天然气地球科学, 2014, 25(12): 2065-2071. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX201412024.htmGUO Zhenzhen, LI Zhiping, LAI Fengpeng, et al. Characteristics of gas well inflow performance with sulfur deposition[J]. Natural Gas Geoscience, 2014, 25(12): 2065-2071. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX201412024.htm [21] 杨学锋, 胡勇, 钟兵, 等. 高含硫气藏中元素硫沉积形态和微观分布研究[J]. 西南石油大学学报(自然科学版), 2009, 31(6): 97-100. https://www.cnki.com.cn/Article/CJFDTOTAL-XNSY200906022.htmYANG Xuefeng, HU Yong, ZHONG Bing, et al. The deposition pattern and micro-distribution study on elemental sulfur in the high sulfur content gas reservoirs[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2009, 31(6): 97-100. https://www.cnki.com.cn/Article/CJFDTOTAL-XNSY200906022.htm [22] 李周, 罗卫华, 赵慧言, 等. 硫吸附和地层水存在下的单质硫沉积规律研究[J]. 天然气地球科学, 2015, 26(12): 2360-2364. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX201512017.htmLI Zhou, LUO Weihua, ZHAO Huiyan, et al. The laws of sulfur deposition considering presence of elemental sulfur adsorption and formation water[J]. Natural Gas Geoscience, 2015, 26(12): 2360-2364. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX201512017.htm [23] 李滔, 李闽, 荆雪琪, 等. 孔隙尺度各向异性与孔隙分布非均质性对多孔介质渗透率的影响机理[J]. 石油勘探与开发, 2019, 46(3): 569-579. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201903016.htmLI Tao, LI Min, JING Xueqi, et al. Influence mechanism of pore-scale anisotropy and pore distribution heterogeneity on permeability of porous media[J]. Petroleum Exploration and Development, 2019, 46(3): 569-579. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201903016.htm [24] LAI Jin, WANG Guiwen, WANG Ziyuan, et al. A review on pore structure characterization in tight sandstones[J]. Earth-Science Reviews, 2018, 177: 436-457. http://www.researchgate.net/profile/Jin_Lai/publication/321711035_A_review_on_pore_structure_characterization_in_tight_sandstones/links/5ba9138ba6fdccd3cb6f8327/A-review-on-pore-structure-characterization-in-tight-sandstones.pdf [25] 陶伟, 邹艳荣, 刘金钟, 等. 压力对粘土矿物催化生烃的影响[J]. 天然气地球科学, 2008, 19(4): 548-552. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX200804020.htmTAO Wei, ZOU Yanrong, LIU Jinzhong, et al. Influence of pressure on hydrocarbon generation under catalytic clays[J]. Natural Gas Geoscience, 2008, 19(4): 548-552. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX200804020.htm [26] 国家能源局. SY/T 7410.1-2018, 岩石三维孔隙结构测定方法第1部分: CT扫描法[S]. 北京: 石油工业出版社, 2018.National Energy Administration. SY/T 7410.1-2018, 3D pore structure characterization of rocks part 1: CT scanning method[S]. Beijing: Petroleum Industry Press, 2018. [27] 国家市场监督管理总局, 国家标准化管理委员会. GB/T 13610-2020, 天然气的组成分析气相色谱法[S]. 北京: 中国标准出版社, 2020.State Administration of Market Regulation, Standardization Administration of China. GB/T 13610-2020, Analysis of natural gas composition: gas chromatography[S]. Beijing: Standards Press of China, 2020. [28] 国家能源局. SY/T 5162-2021, 岩石样品扫描电子显微镜分析方法[S]. 北京: 石油工业出版社, 2021.National Energy Administration. SY/T 5162-2021, Analytical method for rock samples by scanning electron microscope[S]. Beijing: Petroleum Industry Press, 2021. [29] 国家能源局. SY/T 6189-2018, 岩石矿物能谱定量分析方法[S]. 北京: 石油工业出版社, 2018.National Energy Administration. SY/T 6189-2018, Quantitative analysis method for rock minerals by X-ray energy spectrum (EDS)[S]. Beijing: Petroleum Industry Press, 2018. [30] 彭松, 姜贻伟, 宿亚仙, 等. 普光气田高含H2S天然气中硫含量及临界析出压力测定[J]. 石油实验地质, 2018, 40(4): 573-576. doi: 10.11781/sysydz201804573PENG Song, JIANG Yiwei, SU Yaxian, et al. Content determination and critical precipitation pressure of elemental sulfur in sour gas rich in H2S in Puguang Gas Field[J]. Petroleum Geology & Experiment, 2018, 40(4): 573-576. doi: 10.11781/sysydz201804573 -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号