Combined multi-scale characterization of pores in ultra-thick coal seams of Jurassic Xishanyao Formation, Tiaohu-Malang sags, Santanghu Basin

-

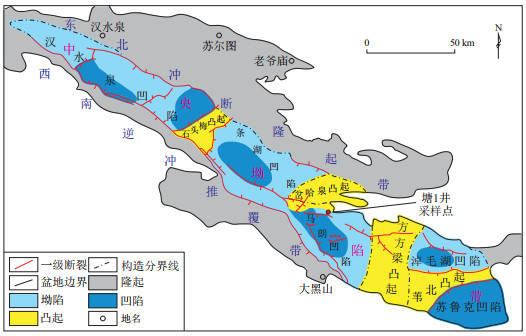

摘要: 三塘湖盆地侏罗系西山窑组中下部巨厚煤层分布广泛,然而目前对于巨厚煤层孔隙特征的研究较少。为精细表征盆地条湖—马朗凹陷煤储层孔隙特征,以西山窑组9-1和9-2煤为研究对象,通过高压压汞、低温液氮吸附、核磁共振、CT扫描、扫描电镜等实验手段和孔隙—裂隙分析系统(PCAS)探究其孔隙发育特征。结果表明,两煤分层煤样表面形貌差异较大,9-1煤表面含有大量矿物晶体颗粒,气孔、角砾孔、摩擦孔以及微裂隙发育,孔裂隙拓扑结构明显,9-2煤具有明显的原生纤维结构,裂隙规模小而分散。两煤层孔隙结构分形特征差异明显,9-1煤比9-2煤非均质性更强,液氮吸附曲线属于Ⅱ型,存在H4型曲线滞后环。9-2煤微孔和小孔分维值分别为2.53和2.63,复杂程度更高,渗流孔连通性更强。煤样多重分形特征表明,小孔径孔隙分布较集中,分布范围较小,该孔径段非均质性更强,其中9-1煤孔径分布集中性更强,孔径分布间隔相对更均匀。采用联合表征煤样全尺度孔径分布特征,9-2煤总孔容大于9-1煤,大孔体积占比最大,分别为47.97%和44.48%,其次为中孔和小孔,微孔占比最少;微孔对两煤层孔比表面积贡献最大,分别为62.67%和58.43%;9-1煤各孔径的孔容贡献率与孔径大小呈正相关,而孔比表面积与孔径大小呈负相关。Abstract: The ultra-thick coal seams in the middle and lower parts of the Jurassic Xishanyao Formation in the Santanghu Basin are widely distributed. However, research on the pore characteristics of these ultra-thick coal seams is limited. To accurately characterize the porosity features of these coal reservoirs in the Tiaohu-Malang sags of the Santanghu Basin, the study examined the 9-1 and 9-2 coal samples of the Xishanyao Formation. Techniques such as high-pressure mercury intrusion porosimetry, low-temperature liquid nitrogen adsorption, nuclear magnetic resonance (NMR), CT scanning, scanning electron microscopy (SEM), and the pore-crack analysis system (PCAS) were used to investigate pore development characteristics. The results show significant differences in surface morphology between the two coal seam samples. The surface of the 9-1 coal sample contains a large number of mineral crystal particles, with well-developed pores, breccia pores, friction holes, and micro-fractures, displaying a distinct pore-fracture topological structure. The 9-2 coal sample exhibits prominent primary fibrous structures, with smaller and more dispersed fractures. The fractal characteristics of the pore structures also differ significantly between the two coal seams, with the 9-1 coal sample showing stronger heterogeneity. Its liquid nitrogen adsorption curves correspond to type Ⅱ with a H4 hysteresis loop. For the 9-2 coal sample, the fractal dimensions of micropores and small pores are 2.53 and 2.63, respectively, indicating higher complexity and better permeability connectivity. Multifractal characteristics analysis shows that pores of small diameters exhibit a more concentrated distribution and a narrower range, with stronger heterogeneity. The pore distribution of 9-1 coal sample is more concentrated, with a relatively more uniform pore size distribution intervals. Using a combined full-scale characterization method, it is revealed that 9-2 coal sample has a higher total pore volume than 9-1. Macropores have the largest volume proportion, accounting for 47.97% and 44.48%, respectively, followed by mesopores and small pores, and the proportion of micropores is the smallest. Micropores contribute the most to the pore specific surface areas for both seams, which are 62.67% and 58.43%, respectively. For the 9-1 coal sample, the pore volume contribution positively correlates with pore size, while the specific surface area contribution negatively correlates with pore size.

-

Key words:

- coal reservoir /

- pore-crack analysis system /

- multi-scale pore /

- multifractal /

- Tiaohu-Malang sags /

- Santanghu Basin

-

表 1 测试煤样的工业分析组分与显微组分

Table 1. Industrial analysis and maceral components of tested coal samples

煤样 取样点深度/m 显微组分/% 工业组分/% 水分 灰分 挥发分 固定碳 镜质组 惰质组 壳质组 9-1 1 002.2 3.44 2.51 29.64 64.41 38.40 58.40 3.2 9-2 1 034.4 3.47 2.60 34.29 59.64 41.70 54.90 3.4 表 2 三塘湖盆地条湖—马朗凹陷侏罗系西山窑组煤样PCAS分析结果

Table 2. PCAS analysis results of coal samples from Jurassic Xishanyao Formation in Tiaohu-Malang sags, Santanghu Basin

煤样 放大倍数 平均面积/nm2 平均周长/nm 平均形状系数 分形维数 面孔率/% 9-1 500 492.06 285.99 0.249 6 1.350 0 3.28 9-2 500 489.72 276.90 0.260 4 1.280 1 4.08 表 3 三塘湖盆地条湖—马朗凹陷侏罗系西山窑组煤压汞校正结果

Table 3. Mercury intrusion calibration results of coal samples from Jurassic Xishanyao Formation of Tiaohu-Malang sags, Santanghu Basin

样品 kc/(10-10 m2/N) 进汞量/(cm3/g) 误差/% 校正前 校正后 9-1 1.089 0.082 2 0.058 3 29.1 9-2 1.181 0.123 8 0.097 2 21.5 表 4 三塘湖盆地条湖—马朗凹陷侏罗系西山窑组煤液氮吸附测试各孔径段比表面积及孔容比例

Table 4. Specific surface area and pore volume ratio of each pore size of coal samples from Jurassic Xishanyao Formation in Tiaohu-Malang sags, Santanghu Basin, tested by liquid nitrogen adsorption experiments

煤样 各孔径段孔容/(cm3/g) 各孔径段比例/% 各孔径段比表面积/(m2/g) 各孔径段比例/% 微孔 小孔 微孔 小孔 微孔 小孔 微孔 小孔 9-1 0.003 3 0.004 5 42.64 57.36 1.178 3 0.410 0 74.18 25.82 9-2 0.002 9 0.008 0 26.30 73.70 1.301 9 0.460 4 73.88 26.12 表 5 三塘湖盆地条湖—马朗凹陷侏罗系西山窑组煤全尺度孔径分布

Table 5. Full-scale pore size distribution of coal samples from Jurassic Xishanyao Formation in Tiaohu-Malang sags, Santanghu Basin

煤样 孔容占比/% 孔比表面积占比/% 微孔 小孔 中孔 大孔 微孔 小孔 中孔 大孔 9-1 4.00 10.99 37.04 47.97 62.67 24.69 12.06 0.58 9-2 2.89 8.98 43.64 44.48 58.43 21.71 18.79 1.07 -

[1] 徐凤银, 肖芝华, 陈东, 等. 我国煤层气开发技术现状与发展方向[J]. 煤炭科学技术, 2019, 47(10): 205-215.XU Fengyin, XIAO Zhihua, CHEN Dong, et al. Current status and development direction of coalbed methane exploration technology in China[J]. Coal Science and Technology, 2019, 47(10): 205-215. [2] 陶树, 汤达祯, 许浩, 等. 沁南煤层气井产能影响因素分析及开发建议[J]. 煤炭学报, 2011, 36(2): 194-198.TAO Shu, TANG Dazhen, XU Hao, et al. Analysis on influence factors of coalbed methane wells productivity and development proposals in southern Qinshui Basin[J]. Journal of China Coal Society, 2011, 36(2): 194-198. [3] 李勇, 徐立富, 刘宇, 等. 深部煤层气水赋存机制、环境及动态演化[J]. 煤田地质与勘探, 2024, 52(2): 40-51.LI Yong, XU Lifu, LIU Yu, et al. Occurrence mechanism, environment and dynamic evolution of gas and water in deep coal seams[J]. Coal Geology & Exploration, 2024, 52(2): 40-51. [4] 陈跃, 汤达祯, 许浩, 等. 基于测井信息的韩城地区煤体结构的分布规律[J]. 煤炭学报, 2013, 38(8): 1435-1442.CHEN Yue, TANG Dazhen, XU Hao, et al. The distribution of coal structure in Hancheng based on well logging data[J]. Journal of China Coal Society, 2013, 38(8): 1435-1442. [5] 姚艳斌, 刘大锰. 基于核磁共振弛豫谱的煤储层岩石物理与流体表征[J]. 煤炭科学技术, 2016, 44(6): 14-22.YAO Yanbin, LIU Dameng. Petrophysics and fluid properties characterizations of coalbed methane reservoir by using NMR relaxation time analysis[J]. Coal Science and Technology, 2016, 44(6): 14-22. [6] 姚艳斌, 刘大锰, 蔡益栋, 等. 基于NMR和X-CT的煤的孔裂隙精细定量表征[J]. 中国科学(地球科学), 2010, 40(11): 1598-1607.YAO Yanbin, LIU Dameng, CAI Yidong, et al. Advanced characterization of pores and fractures in coals by nuclear magnetic resonance and X-ray computed tomography[J]. Science China(Earth Sciences), 2010, 53(6): 854-862. [7] 付裕, 陈新, 冯中亮. 基于CT扫描的煤岩裂隙特征及其对破坏形态的影响[J]. 煤炭学报, 2020, 45(2): 568-578.FU Yu, CHEN Xin, FENG Zhongliang. Characteristics of coal-rock fractures based on CT scanning and its influence on failure modes[J]. Journal of China Coal Society, 2020, 45(2): 568-578. [8] 翟成, 孙勇, 范宜仁, 等. 低场核磁共振技术在煤孔隙结构精准表征中的应用与展望[J]. 煤炭学报, 2022, 47(2): 828-848.ZHAI Cheng, SUN Yong, FAN Yiren, et al. Application and prospect of low-field nuclear magnetic resonance technology in accurate characterization of coal pore structure[J]. Journal of China Coal Society, 2022, 47(2): 828-848. [9] YAO Yanbin, LIU Dameng. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals[J]. Fuel, 2012, 95: 152-158. doi: 10.1016/j.fuel.2011.12.039 [10] 楚亚培. 液氮冻融煤体孔隙裂隙结构损伤演化规律及增渗机制研究[D]. 重庆: 重庆大学, 2020.CHU Yapei. Study on the damage evolution law of pore and fracture structure of coal under liquid nitrogen freeze-thaw and the mechanism of permeability enhancing[D]. Chongqing: Chongqing University, 2020. [11] 降文萍, 宋孝忠, 钟玲文. 基于低温液氮实验的不同煤体结构煤的孔隙特征及其对瓦斯突出影响[J]. 煤炭学报, 2011, 36(4): 609-614.JIANG Wenping, SONG Xiaozhong, ZHONG Lingwen. Research on the pore properties of different coal body structure coals and the effects on gas outburst based on the low-temperature nitrogen adsorption method[J]. Journal of China Coal Society, 2011, 36(4): 609-614. [12] DONG Kai, ZHONG Dongliang, LU Yiyu, et al. Facilitating desorption and diffusion of coalbed methane by wetting-corrosion: perspectives from the change of pore structure[J]. Gas Science and Engineering, 2023, 119: 205138. doi: 10.1016/j.jgsce.2023.205138 [13] LI Teng, WU Jianjun, WANG Xinggang, et al. Particle size effect and temperature effect on the pore structure of low-rank coal[J]. ACS Omega, 2021, 6(8): 5865-5877. doi: 10.1021/acsomega.0c06280 [14] 李天, 任大忠, 甯波, 等. 煤层孔隙结构多尺度联合表征及其对可动流体的影响[J]. 矿业科学学报, 2023, 8(4): 569-582.LI Tian, REN Dazhong, NING Bo, et al. Multi-scale joint characterization of coal seam pore structure and its influence on movable fluid[J]. Journal of Mining Science and Technology, 2023, 8(4): 569-582. [15] 杨明, 柳磊, 刘佳佳, 等. 中阶煤孔隙结构的氮吸附—压汞—核磁共振联合表征研究[J]. 煤炭科学技术, 2021, 49(5): 67-74.YANG Ming, LIU Lei, LIU Jiajia, et al. Study on joint characterization of pore structure of middle-rank coal by nitrogen adsorption- mercury intrusion-NMR[J]. Coal Science and Technology, 2021, 49(5): 67-74. [16] LIU Chun, SHI Bin, ZHOU Jian, et al. Quantification and characterization of microporosity by image processing, geometric measurement and statistical methods: application on SEM images of clay materials[J]. Applied Clay Science, 2011, 54(1): 97-106. doi: 10.1016/j.clay.2011.07.022 [17] 韩贝贝, 秦勇, 张政, 等. 基于压汞试验的煤可压缩性研究及压缩量校正[J]. 煤炭科学技术, 2015, 43(3): 68-72.HAN Beibei, QIN Yong, ZHANG Zheng, et al. Study on coal compressibility and correction of compression amount based on compressibility of mercury injection test[J]. Coal Science and Technology, 2015, 43(3): 68-72. [18] 胡彬彬, 张晓阳, 李康, 等. 老厂矿区煤储层孔隙结构特征及全尺度表征[J]. 煤炭科学技术, 2023, 51(S2): 165-174. doi: 10.12438/cst.2022-1743HU Binbin, ZHANG Xiaoyang, LI Kang, et al. Pore structure characteristics and full-scale characterization of coal reservoirs in the Laochang mining area[J]. Coal Science and Technology, 2023, 51(S2): 165-174. doi: 10.12438/cst.2022-1743 [19] 李玲, 汤达祯, 许浩, 等. 中煤阶煤岩控制下的煤储层孔裂隙结构特征: 以柳林矿区为例[J]. 中国科技论文, 2015, 10(9): 1058-1065. doi: 10.3969/j.issn.2095-2783.2015.09.014LI Ling, TANG Dazhen, XU Hao, et al. Pore and fissure structure characteristics of medium rank coal under the control of coal petrology: taking Liulin mining area as the example[J]. China Sciencepaper, 2015, 10(9): 1058-1065. doi: 10.3969/j.issn.2095-2783.2015.09.014 [20] 李松, 汤达祯, 许浩, 等. 应力条件制约下不同埋深煤储层物性差异演化[J]. 石油学报, 2015, 36(S1): 68-75. doi: 10.7623/syxb2015S1008LI Song, TANG Dazhen, XU Hao, et al. Evolution of physical differences in various buried depth of coal reservoirs under constraint of stress[J]. Acta Petrolei Sinica, 2015, 36(S1): 68-75. doi: 10.7623/syxb2015S1008 [21] 卢杰林. 不同煤阶煤孔径结构特征及全孔径拼接表征[D]. 徐州: 中国矿业大学, 2021.LU Jielin. Characterization of pore structure and full aperture splicing of coal with different coal ranks[D]. Xuzhou: China University of Mining and Technology, 2021. [22] 刘怀谦, 王磊, 谢广祥, 等. 煤体孔隙结构综合表征及全孔径分形特征[J]. 采矿与安全工程学报, 2022, 39(3): 458-469.LIU Huaiqian, WANG Lei, XIE Guangxiang, et al. Comprehensive characterization and full pore size fractal characteristics of coal pore structure[J]. Journal of Mining and Safety Engineering, 2022, 39(3): 458-469. [23] 张俭让, 卢亚楠, 刘恒, 等. 合阳矿区煤体孔隙结构对瓦斯吸附—渗流特性影响的实验研究[J]. 煤矿安全, 2018, 49(8): 19-22.ZHANG Jianrang, LU Yanan, LIU Heng, et al. Experimental study on influence of coal pore structure on gas adsorption and seepage characteristics in Heyang mining area[J]. Safety in Coal Mines, 2018, 49(8): 19-22. [24] POMONIS P J, TSAOUSI E T. Frenkel Halsey Hill equation, dimensionality of adsorption, and pore anisotropy[J]. Langmuir, 2009, 25(17): 9986-9994. doi: 10.1021/la901121c [25] 李子文, 林柏泉, 郝志勇, 等. 煤体多孔介质孔隙度的分形特征研究[J]. 采矿与安全工程学报, 2013, 30(3): 437-442.LI Ziwen, LIN Boquan, HAO Zhiyong, et al. Fractal characteristics of porosity for porous media in coal mass[J]. Journal of Mining & Safety Engineering, 2013, 30(3): 437-442. [26] 任伟光. 深部煤体孔裂隙结构的多尺度分形表征及渗透机理研究[D]. 北京: 中国矿业大学(北京), 2022.REN Weiguang. The study on multiscale fractal characterization and permeability mechanism of pore structure in deep coal[D]. Beijing: China University of Mining & Technology (Beijing), 2022. [27] LI Zhongbei, REN Ting, LI Xiangchun, et al. Full-scale pore structure characterization of different rank coals and its impact on gas adsorption capacity: a theoretical model and experimental study[J]. Energy, 2023, 277: 127621. doi: 10.1016/j.energy.2023.127621 [28] 张苗, 刘钦节, 王兴阵, 等. 整合压汞、N2和CO2吸附的中—高阶煤多重分形特征[J]. 煤炭学报, 2024, 49(5): 2394-2404.ZHANG Miao, LIU Qinjie, WANG Xingzhen, et al. Multiple fractal characterization of medium-high rank coal integrating mercury intrusion porosimetry, N2 and CO2 adsorption experiments[J]. Journal of China Coal Society, 2024, 49(5): 2394-2404. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号