Study on microscopic pore structures and mechanical properties

-

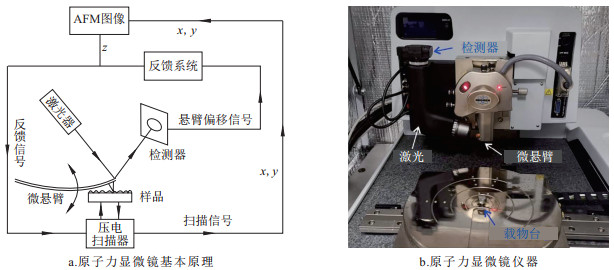

摘要: 煤岩孔隙结构与力学性质是煤层气地质评价的关键参数,反映煤的储集性与可压性。以山西沁水、大同等盆地4块煤样(大同侏罗系煤、镜质体反射率Ro=0.91%,古交山西组2号煤、Ro=1.34%,古交太原组8号煤、Ro=1.70%,翼城山西组2号煤、Ro= 1.77%)为研究对象,基于原子力显微镜实验,利用图像分割法与Derjaguin-Muller-Toporov力学模型建立微观孔隙结构与力学性质联合表征技术,明确煤样的微观孔隙结构与力学性质,揭示了物质组成、孔隙结构及热演化程度对微观力学性质的影响。结果表明,煤样的面孔率主要分布于2.72%~4.60%,平均3.58%;总孔表面积为(3.413~5.638)×10-2 μm2/μm2,总孔容为(0.5~3.9)×10-4 μm3/μm2,孔径主要分布于10~100 nm,杨氏模量分布于2.24~3.10 GPa,平均2.77 GPa。煤的力学性质受到物质组成、孔隙结构与热演化程度的共同作用,随着水分的减少、挥发分与矿物含量的增加,杨氏模量呈现增大趋势;表面粗糙度、平均孔径、面孔率、比表面积及总孔容增大,杨氏模量表现出减小趋势;随着热演化程度增加,杨氏模量减小。基于原子力显微镜可同步揭示煤岩微观孔隙结构与力学性质,为煤储层储集性与力学研究提供新方法与新思路,对于非常规储层储集性评价及可压性研究具有重要意义。Abstract: The pore structures and mechanical properties of coal are key parameters for geological evaluation of coalbed methane, reflecting its reservoir capacity and compressibility. The study investigated four coal samples from the Qinshui and Datong basins in Shanxi Province, including Jurassic coal from Datong (Ro=0.91%), No. 2 coal from the Shanxi Formation in Gujiao (Ro=1.34%), No. 8 coal of the Taiyuan Formation in Gujiao (Ro=1.70%), and No. 2 coal of the Shanxi Formation in Yicheng (Ro=1.77%). Using atomic force microscopy (AFM), a combined characterization technique was established for microscopic pore structure and mechanical properties based on image segmentation and Derjaguin-Muller-Toporov (DMT) mechanical model. This method clarified the microscopic pore structure and mechanical properties of coal samples and revealed the influence of material composition, pore structure, and thermal evolution level on their microscopic mechanical properties. The results showed that the surface porosity of coal samples mainly ranged from 2.72% to 4.60%, with an average of 3.58%. The total pore surface area and total pore volume were (3.413-5.638)×10-2 μm2/μm2 and (0.5-3.9)×10-4 μm3/μm2, respectively. The pore sizes were mainly distributed between 10-100 nm, and the Young's modulus ranged from 2.24 to 3.10 GPa, with an average of 2.77 GPa. The mechanical properties of coal were influenced by the material composition, pore structure, and thermal evolution level. As moisture decreased and volatile and mineral content increased, the Young's modulus showed an increasing trend. With an increase in surface roughness, mean pore size, porosity surface, specific surface area, and total pore volume, the Young's modulus decreased. As thermal evolution progressed, the Young's modulus decreased. AFM enables simultaneous analysis of microscopic pore structure and mechanical properties of coal, providing new methods and insights for studying reservoir capacity and mechanical behavior of coal reservoirs. It holds significant implications for the evaluation of reservoir capacity and compressibility in unconventional reservoirs.

-

表 1 不同地区煤样工业组分及演化程度参数

Table 1. Parameters of industrial components and thermal evolution levels of coal samples from different regions

样品来源 样品编号 Ro/% 工业组分含量/% Mad Aad Vad FCad 忻州窑侏罗系煤 XZ-1 0.91 0.78 25.40 25.02 48.80 原相矿区2号煤 GJ2-1 1.34 2.35 16.24 14.45 66.95 原相矿区8号煤 GJ8-1 1.70 0.86 13.65 17.81 67.68 上河矿区2号煤 SH-1 1.77 0.77 6.47 15.24 77.52 注:Ro.镜质体反射率;Mad.空气干燥基水分;Aad.空气干燥基灰分;Vad.空气干燥基挥发分;FCad.空气干燥基固定碳。 表 2 不同地区煤样表面粗糙度评价结果

Table 2. Evaluation results of surface roughness of coal samples from different regions

样品编号 Ro/% Ra/nm Rq/nm Rsk Rku XZ-1 0.91 0.73 0.97 0.50 0.83 GJ2-1 1.34 1.34 1.87 1.94 21.18 GJ8-1 1.70 0.78 1.01 0.16 0.76 SH-1 1.77 0.95 1.45 0.72 6.08 表 3 煤样孔隙结构评价结果

Table 3. Evaluation results of pore structures of coal samples

样品编号 孔隙数量/个 面孔率/% 平均孔径/nm 总孔表面积/(μm2/μm2) 总孔容/(μm3/μm2) XZ-1 338 2.72 103 3.413 0.005 GJ2-1 637 4.60 104 5.638 0.039 GJ8-1 352 4.03 129 5.259 0.011 SH-1 467 2.95 94 3.631 0.023 -

[1] 郭旭升, 周德华, 赵培荣, 等. 鄂尔多斯盆地石炭系—二叠系煤系非常规天然气勘探开发进展与攻关方向[J]. 石油与天然气地质, 2022, 43(5): 1013-1023.GUO Xusheng, ZHOU Dehua, ZHAO Peirong, et al. Progresses and directions of unconventional natural gas exploration and development in the Carboniferous-Permian coal measure strata, Ordos Basin[J]. Oil & Gas Geology, 2022, 43(5): 1013-1023. [2] 张千贵, 李权山, 范翔宇, 等. 中国煤与煤层气共采理论技术现状及发展趋势[J]. 天然气工业, 2022, 42(6): 130-145. doi: 10.3787/j.issn.1000-0976.2022.06.011ZHANG Qiangui, LI Quanshan, FAN Xiangyu, et al. Current situation and development trend of theories and technologies for coal and CBM co-mining in China[J]. Natural Gas Industry, 2022, 42(6): 130-145. doi: 10.3787/j.issn.1000-0976.2022.06.011 [3] 周德华, 陈刚, 陈贞龙, 等. 中国深层煤层气勘探开发进展、关键评价参数与前景展望[J]. 天然气工业, 2022, 42(6): 43-51. doi: 10.3787/j.issn.1000-0976.2022.06.004ZHOU Dehua, CHEN Gang, CHEN Zhenlong, et al. Exploration and development progress, key evaluation parameters and prospect of deep CBM in China[J]. Natural Gas Industry, 2022, 42(6): 43-51. doi: 10.3787/j.issn.1000-0976.2022.06.004 [4] 李勇, 徐立富, 张守仁, 等. 深煤层含气系统差异及开发对策[J]. 煤炭学报, 2023, 48(2): 900-917.LI Yong, XU Lifu, ZHANG Shouren, et al. Gas bearing system difference in deep coal seams and corresponded development strategy[J]. Journal of China Coal Society, 2023, 48(2): 900-917. [5] 郭涛, 金晓波, 武迪迪, 等. 川东南南川区块龙潭组深部煤层气成藏特征及勘探前景[J]. 煤田地质与勘探, 2024, 52(4): 60-67.GUO Tao, JIN Xiaobo, WU Didi, et al. Accumulation characteristics and exploration prospects of deep coalbed methane in the Longtan Formation of the Nanchuan block on the southeastern margin of the Sichuan Basin[J]. Coal Geology & Exploration, 2024, 52(4): 60-67. [6] 何发岐, 董昭雄. 深部煤层气资源开发潜力: 以鄂尔多斯盆地大牛地气田为例[J]. 石油与天然气地质, 2022, 43(2): 277-285.HE Faqi, DONG Zhaoxiong. Development potential of deep coalbed methane: a case study in the Daniudi gas field, Ordos Basin[J]. Oil & Gas Geology, 2022, 43(2): 277-285. [7] LI Jijun, YIN Jianxin, ZHANG Yanian, et al. A comparison of experimental methods for describing shale pore features: a case study in the Bohai Bay Basin of eastern China[J]. International Journal of Coal Geology, 2015, 152: 39-49. doi: 10.1016/j.coal.2015.10.009 [8] 孔令运, 宋广朋, 蒋恕, 等. 深层页岩微观力学特征及控制机理: 以涪陵地区平桥区块JYA井深层页岩为例[J]. 石油实验地质, 2024, 46(4): 683-697. doi: 10.11781/sysydz202404683KONG Lingyun, SONG Guangpeng, JIANG Shu, et al. Micromechanical characteristics and controlling mechanism of deep shale: a case study of well JYA in Pingqiao block, Fuling area[J]. Petroleum Geology & Experiment, 2024, 46(4): 683-697. doi: 10.11781/sysydz202404683 [9] 陈立超, 张典坤, 吕帅锋, 等. 海/陆相页岩微观力学性质压痕测试研究[J]. 油气地质与采收率, 2022, 29(6): 31-38.CHEN Lichao, ZHANG Diankun, LV Shuaifeng, et al. Micromechanical characteristics of marine/continental shale based on indentation test[J]. Petroleum Geology and Recovery Efficiency, 2022, 29(6): 31-38. [10] GOLUBEV Y A, KOVALEVA O V, YUSHKIN N P. Observations and morphological analysis of supermolecular structure of natural bitumens by atomic force microscopy[J]. Fuel, 2008, 87(1): 32-38. doi: 10.1016/j.fuel.2007.04.005 [11] 李俊乾, 刘大锰, 卢双舫, 等. 中高煤阶煤岩弹性模量及其影响因素试验研究[J]. 煤炭科学技术, 2016, 44(1): 102-108.LI Junqian, LIU Dameng, LU Shuangfang, et al. Experimental study on elastic modulus of medium-high rank coals and its influencing factors[J]. Coal Science and Technology, 2016, 44(1): 102-108. [12] 王濡岳, 胡宗全, 董立, 等. 页岩气储层表征评价技术进展与思考[J]. 石油与天然气地质, 2021, 42(1): 54-65.WANG Ruyue, HU Zongquan, DONG Li, et al. Advancement and trends of shale gas reservoir characterization and evaluation[J]. Oil & Gas Geology, 2021, 42(1): 54-65. [13] 张琴, 刘畅, 梅啸寒, 等. 页岩气储层微观储集空间研究现状及展望[J]. 石油与天然气地质, 2015, 36(4): 666-674.ZHANG Qin, LIU Chang, MEI Xiaohan, et al. Status and prospect of research on microscopic shale gas reservoir space[J]. Oil & Gas Geology, 2015, 36(4): 666-674. [14] 余晓露, 李龙龙, 蒋宏, 等. 融合图像处理与深度学习的亮晶颗粒灰岩岩相学分析应用[J]. 石油实验地质, 2023, 45(5): 1026-1038.YU Xiaolu, LI Longlong, JIANG Hong, et al. Application of sparry grain limestone petrographic analysis combining image processing and deep learning[J]. Petroleum Geology & Experiment, 2023, 45(5): 1026-1038. [15] 王建丰, 杨超, 柳宇柯, 等. 纳米压痕技术在页岩力学性质表征中的应用进展[J]. 石油与天然气地质, 2022, 43(2): 477-488.WANG Jianfeng, YANG Chao, LIU Yuke, et al. Review on the application of nanoindentation to study of shale mechanical property[J]. Oil & Gas Geology, 2022, 43(2): 477-488. [16] 郭敬杰, 李伟, 韩祥凯, 等. 基于纳米压痕的构造煤与原生煤结构面力学特性[J]. 中国矿业大学学报, 2024, 53(3): 509-523.GUO Jingjie, LI Wei, HAN Xiangkai, et al. Mechanical properties instructural planes of tectonic coal and primary coal through nano-indentation[J]. Journal of China University of Mining & Technology, 2024, 53(3): 509-523. [17] 刘鹏, 赵渝龙, 聂百胜, 等. 煤体微观力学特性的纳米压痕实验研究[J]. 煤炭学报, 2024, 49(8): 3453-3467.LIU Peng, ZHAO Yulong, NIE Baisheng, et al. Study on nano-mechanical behavior of coal using nanoindentation tests[J]. Journal of China Coal Society, 2024, 49(8): 3453-3467. [18] 余昊, 沈瑞, 郭和坤, 等. 原子力显微镜在页岩储层表征中的应用进展[J]. 应用化工, 2023, 52(2): 511-516. doi: 10.3969/j.issn.1671-3206.2023.02.036YU Hao, SHEN Rui, GUO Hekun, et al. Application progress of atomic force microscopy in shale reservoir characterization[J]. Applied Chemical Industry, 2023, 52(2): 511-516. doi: 10.3969/j.issn.1671-3206.2023.02.036 [19] LIU Jiaxun, JIANG Xiumin, HUANG Xiangyong, et al. Morphological characterization of super fine pulverized coal particle. Part 2. AFM investigation of single coal particle[J]. Fuel, 2010, 89(12): 3884-3891. doi: 10.1016/j.fuel.2010.07.001 [20] YAO Suping, JIAO Kun, ZHANG Ke, et al. An atomic force microscopy study of coal nanopore structure[J]. Chinese Science Bulletin, 2011, 56(25): 2706-2712. doi: 10.1007/s11434-011-4623-8 [21] PAN Jienan, ZHU Haitao, HOU Quanlin, et al. Macromolecular and pore structures of Chinese tectonically deformed coal studied by atomic force microscopy[J]. Fuel, 2015, 139: 94-101. doi: 10.1016/j.fuel.2014.08.039 [22] ZHAO Shihu, LI Yong, WANG Yanbin, et al. Quantitative study on coal and shale pore structure and surface roughness based on atomic force microscopy and image processing[J]. Fuel, 2019, 244: 78-90. doi: 10.1016/j.fuel.2019.02.001 [23] LI Yong, YANG Jianghao, PAN Zhejun, et al. Nanoscale pore structure and mechanical property analysis of coal: an insight combining AFM and SEM images[J]. Fuel, 2020, 260: 116352. doi: 10.1016/j.fuel.2019.116352 [24] 杨江浩, 李勇, 吴翔, 等. 基于原子力显微镜的煤岩微尺度力学性质研究[J]. 煤炭科学技术, 2019, 47(9): 144-151.YANG Jianghao, LI Yong, WU Xiang, et al. Study on micro-scale mechanical properties of coal rock based on atomic force micro- scopy[J]. Coal Science and Technology, 2019, 47(9): 144-151. [25] JAFARZADEGAN K, MERWADE V. A DEM-based approach for large-scale floodplain mapping in ungauged watersheds[J]. Journal of Hydrology, 2017, 550: 650-662. doi: 10.1016/j.jhydrol.2017.04.053 [26] WU Yanpeng, PENG Xiaoqi, RUAN Kai, et al. Improved image segmentation method based on morphological reconstruction[J]. Multimedia Tools and Applications, 2017, 76(19): 19781-19793. doi: 10.1007/s11042-015-3192-2 [27] DERJAGUIN B V, MULLER V M, TOPOROV Y P. Effect of contact deformations on the adhesion of particles[J]. Journal of Colloid and Interface Science, 1975, 53(2): 314-326. doi: 10.1016/0021-9797(75)90018-1 [28] TRTIK P, KAUFMANN J, VOLZ U. On the use of peak-force tapping atomic force microscopy for quantification of the local elastic modulus in hardened cement paste[J]. Cement and Concrete Research, 2012, 42(1): 215-221. doi: 10.1016/j.cemconres.2011.08.009 [29] DOUKETIS C, WANG Zhouhang, HASLETT T L, et al. Fractal character of cold-deposited silver films determined by low-temperature scanning tunneling microscopy[J]. Physical Review B, 1995, 51(16): 11022-11031. doi: 10.1103/PhysRevB.51.11022 [30] 张娜, 寻兴建, 王帅栋, 等. 煤系沉积岩多重分形维数计算及影响因素分析[J]. 矿业科学学报, 2021, 6(5): 623-632.ZHANG Na, XUN Xingjian, WANG Shuaidong, et al. Calculation of multi-fractal dimension of coal measure sedimentary rock and analysis of influencing factors[J]. Journal of Mining Science and Technology, 2021, 6(5): 623-632. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号