Quantitative study on contribution of dynamic imbibition to oil production during fracturing and huff-n-puff in tight reservoirs

-

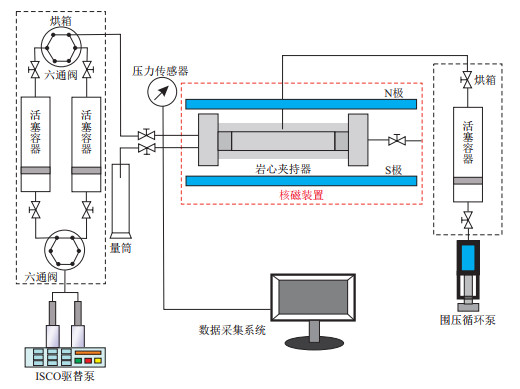

摘要: 致密油藏压裂吞吐是一个动态渗吸过程,主要通过压差驱替作用和自发渗吸作用实现原油增产,但目前尚不清楚这两种增油机理对产油量量化的贡献程度。为研究致密砾岩油藏压裂吞吐采油过程中,动态渗吸增油机理对产油贡献的量化分析问题,借助高温高压多功能岩心驱替系统和高温高压在线驱替核磁共振成像系统,采用天然致密砾岩油藏岩心,开展室内物理模拟实验。首先通过不同类型压裂驱油剂的渗吸特征实验,筛选渗吸效果较好的压裂驱油剂类型;然后依据压裂吞吐采油效果评价实验,优选采油效果最好的压裂驱油剂;最后通过采油效果影响因素实验,对压裂吞吐采油的动态渗吸增油机理进行量化分析。实验结果显示:表面活性剂和流动控制剂的渗吸效果均较好,流动控制剂更有助于提高压裂吞吐的采油效果,渗吸作用和驱替作用在动态渗吸过程中对产油贡献的变化规律是相反的。当压裂驱油剂降低界面张力和改变湿润性的能力较强时,渗吸作用为主要增油机理,反之驱替作用为主要增油机理;表面活性剂和流动控制剂的渗吸效果都比较好,但前者对吞吐轮次的敏感程度较弱,后者的敏感程度较强;焖井时间是影响动态渗吸过程中渗吸/驱替贡献率的主要因素,但驱替贡献率始终大于渗吸贡献率。Abstract: Fracturing and huff-n-puff in tight reservoirs is a dynamic imbibition process, where crude oil recovery is enhanced mainly through two mechanisms: differential pressure displacement and spontaneous imbibition. However, the contribution rate of these two mechanisms to the quantification of overall oil recovery remains unclear. To address this, a quantitative analysis was conducted on the contribution of dynamic imbibition mechanisms during fracturing and huff-n-puff oil recovery in tight conglomerate reservoirs. Laboratory physical simulation experiments were carried out using natural tight conglomerate reservoir cores, utilizing a high-temperature and high-pressure multi-functional core displacement system and a high-temperature and high-pressure online displacement nuclear magnetic resonance imaging system. Firstly, experiments were conducted on the imbibition characteristics of different types of fracturing oil displacement agents, and the agents with superior imbibition effects were screened out. Secondly, based on evaluations of fracturing and huff-n-puff oil recovery, the most effective fracturing oil displacement agent was identified. Finally, through analyzing factors influencing oil recovery, a quantitative assessment of the production enhancement mechanisms of dynamic imbibition in fracturing and huff-n-puff oil recovery was carried out. The experimental results showed that both surfactants and flow control agents exhibited strong imbibition effects, with flow control agents more effective in enhancing fracturing and huff-n-puff oil recovery. Furthermore, the contribution of imbibition and displacement on oil recovery during the dynamic imbibition process showed opposite patterns. The main research conclusions are as follows. Imbibition dominates as the primary oil recovery mechanism when the fracturing oil displacement agent exhibits a strong ability to reduce interfacial tension and alter wettability. Otherwise, displacement becomes the dominant mechanism. Both surfactants and flow control agents demonstrate good imbibition performance. However, surfactants are less sensitive to huff-n-puff cycles, while flow control agents are more sensitive. Shut-in time is the key factor affecting the contribution rate of imbibition or displacement. However, the contribution rate of displacement remains consistently higher than that of imbibition.

-

表 1 岩心物性参数

Table 1. Physical parameters of cores

岩心

编号长度/mm 直径/mm 孔隙度/% 渗透率/10-3 μm2 人造含油

饱和度/%1 47.47 25.01 10.98 0.83 60.38 2 44.78 24.97 16.16 0.43 50.39 3 48.54 25.11 14.51 0.67 61.75 4 49.32 24.91 12.30 1.57 54.21 表 2 压裂驱油剂质量分数及性能参数

Table 2. Mass fractions and performance parameters of fracturing displacement agents

岩心

编号压裂驱油剂

类型质量

分数/%界面张力/(mN/m) 降低界面

张力能力改变

湿润性能力1 表面活性剂 0.2 0.028 强 强 2 纳米驱油剂 0.2 0.141 较强 强 3 流度控制剂 0.2 8.875 一般 较弱 4 KCl溶液 2.0 20.036 弱 弱 表 3 岩心物性参数和吞吐控制参数

Table 3. Core physical parameters and huff-n-puff control parameters

岩心

编号岩心物性参数 吞吐控制参数 长度/mm 直径/mm 孔隙度/% 渗透率/10-3 μm2 压裂驱油剂 焖井时间/min 吞吐轮次 A 71.02 25.02 15.3 0.698 表面活性剂 120 4 B 71.17 24.88 15.2 0.689 流度控制剂 120 4 表 4 岩心物性参数和吞吐控制参数

Table 4. Core physical parameters and huff-n-puff control parameters

岩心

编号岩心物性参数 吞吐控制参数 长度/mm 直径/mm 孔隙度/% 渗透率/10-3 μm2 压裂驱油剂 焖井时间/min 吞吐轮次 C 67.97 25.05 15.2 0.608 流度控制剂 15 4 D 71.17 24.88 14.8 0.457 流度控制剂 120 1 E 72.10 25.02 16.1 0.923 流度控制剂 300 1 F 70.09 25.00 15.9 0.742 流度控制剂 2 880 1 -

[1] 胡泽根, 马宇奔, 李明峰, 等. 致密油提高采收率技术研究进展[J]. 石油化工应用, 2023, 42(3): 5-11.HU Zegen, MA Yuben, LI Mingfeng, et al. Research progress on enhanced oil recovery technology of tight oil[J]. Petrochemical Industry Application, 2023, 42(3): 5-11. [2] 郭建春, 马莅, 卢聪. 中国致密油藏压裂驱油技术进展及发展方向[J]. 石油学报, 2022, 43(12): 1788-1797.GUO Jianchun, MA Li, LU Cong. Progress and development directions of fracturing flooding technology for tight reservoirs in China[J]. Acta Petrolei Sinica, 2022, 43(12): 1788-1797. [3] 刘义坤, 王凤娇, 汪玉梅, 等. 中低渗透储集层压驱提高采收率机理[J]. 石油勘探与开发, 2022, 49(4): 752-759.LIU Yikun, WANG Fengjiao, WANG Yumei, et al. The mechanism of hydraulic fracturing assisted oil displacement to enhance oil recovery in low and medium permeability reservoirs[J]. Petroleum Exploration and Development, 2022, 49(4): 752-759. [4] 王凤娇, 孟详昊, 刘义坤, 等. 致密储层压驱焖井阶段渗吸机理分子模拟研究[J]. 力学学报, 2024, 56(6): 1624-1634.WANG Fengjiao, MENG Xianghao, LIU Yikun, et al. The shut-in imbibition mechanism of hydraulic fracturing-assisted oil displacement in tight reservoirs based on molecular simulation[J]. Chinese Journal of Theoretical and Applied Mechanics, 2024, 56(6): 1624-1634. [5] 孔祥伟, 许洪星, 张晓辉, 等. 低渗透薄互层油藏动态多级暂堵压裂技术优化[J]. 钻采工艺, 2023, 46(6): 66-71KONG Xiangwei, XU Hongxing, ZHANG Xiaohui, et al. Optimization of dynamic multistage temporary plugging fracturing technology for low permeability thin interbed reservoirs[J]. Drilling and Production Technology, 2023, 46(6): 66-71 [6] 钱计安, 蒋裕强, 罗彤彤, 等. 页岩储层渗吸过程微观孔缝演变特征及影响因素: 以四川盆地渝西地区龙马溪组龙一1亚段为例[J]. 石油实验地质, 2024, 46(6): 1336-1348. doi: 10.11781/sysydz2024061336QIAN Ji'an, JIANG Yuqiang, LUO Tongtong, et al. Microscopic pore and fracture evolution characteristics and influencing factors during imbibition process of shale reservoirs: a case study of the first section of the first member of Longmaxi Formation, western Chongqing area, Sichuan Basin[J]. Petroleum Geology & Experiment, 2024, 46(6): 1336-1348. doi: 10.11781/sysydz2024061336 [7] 余海棠, 何亚斌, 刘艳梅, 等. 超低渗透油藏高温高压动态吞吐渗吸驱油实验[J]. 大庆石油地质与开发, 2022, 41(5): 80-86.YU Haitang, HE Yabin, LIU Yanmei, et al. Experiment of high-temperature and high-pressure dynamic huff-n-puff imbibition displacement in ultra-low permeability reservoir[J]. Petroleum Geology & Oilfield Development in Daqing, 2022, 41(5): 80-86. [8] 王香增, 赵习森, 党海龙, 等. 基于核磁共振的致密油藏自发渗吸及驱替特征研究[J]. 地球物理学进展, 2020, 35(5): 1870-1877.WANG Xiangzeng, ZHAO Xisen, DANG Hailong, et al. Research on the characteristics of spontaneous imbibition and displacement of the tight reservoir with the NMR method[J]. Progress in Geophysics, 2020, 35(5): 1870-1877. [9] 党海龙, 王小锋, 崔鹏兴, 等. 基于核磁共振技术的低渗透致密砂岩油藏渗吸驱油特征研究[J]. 地球物理学进展, 2020, 35(5): 1759-1769.DANG Hailong, WANG Xiaofeng, CUI Pengxing, et al. Research on the characteristics of spontaneous imbibition oil displacement with the low permeability tight-sandstone oil reservoir using the Nuclear Magnetic Resonance (NMR) technology[J]. Progress in Geophysics, 2020, 35(5): 1759-1769. [10] 廖凯, 张士诚, 谢勃勃. 页岩油体积压裂后合理焖井时间模拟研究[J]. 油气藏评价与开发, 2024, 14(5): 749-755.LIAO Kai, ZHANG Shicheng, XIE Bobo. Simulation of reasonable shut-in time for shale oil after volume fracturing[J]. Petroleum Reservoir Evaluation and Development, 2024, 14(5): 749-755. [11] 周义博, 刘卫东, 郑晓波, 等. 低渗透油藏渗吸机理及研究状况综述[J]. 应用化工, 2018, 47(4): 825-829.ZHOU Yibo, LIU Weidong, ZHENG Xiaobo, et al. Summary about mechanism and application of imbibition in low-permeability reservoirs[J]. Applied Chemical Industry, 2018, 47(4): 825-829. [12] 李传亮, 毛万义, 吴庭新, 等. 渗吸驱油的机理研究[J]. 新疆石油地质, 2019, 40(6): 687-694.LI Chuanliang, MAO Wanyi, WU Tingxin, et al. A study on mechanism of oil displacement by imbibition[J]. Xinjiang Petroleum Geology, 2019, 40(6): 687-694. [13] 金智荣, 张华丽, 陈佳豪, 等. 低渗储层动静态渗吸采油效果实验研究[J]. 非常规油气, 2022, 9(5): 93-102.JIN Zhirong, ZHANG Huali, CHEN Jiahao, et al. Experimental study on oil displacement effect by dynamic and static imbibition in low permeability reservoir[J]. Unconventional Oil & Gas, 2022, 9(5): 93-102. [14] 王付勇, 曾繁超, 赵久玉. 低渗透/致密油藏驱替—渗吸数学模型及其应用[J]. 石油学报, 2020, 41(11): 1396-1405.WANG Fuyong, ZENG Fanchao, ZHAO Jiuyu. A mathematical model of displacement and imbibition of low-permeability/tight reservoirs and its application[J]. Acta Petrolei Sinica, 2020, 41(11): 1396-1405. [15] 杨宸, 杨二龙, 安艳明, 等. 致密储层孔隙结构对渗吸的影响研究进展[J]. 特种油气藏, 2024, 31(4): 10-18.YANG Chen, YANG Erlong, AN Yanming, et al. Research progress on the impact of tight oil reservoir pore structure on spontaneous imbibition[J]. Special Oil & Gas Reservoirs, 2024, 31(4): 10-18. [16] 石立华, 薛颖, 崔鹏兴, 等. 致密油藏自发静态渗吸实验及影响因素[J]. 科学技术与工程, 2023, 23(29): 12494-12503.SHI Lihua, XUE Ying, CUI Pengxing, et al. Spontaneous static imbibition experiment of tight reservoir and its influencing factors[J]. Science Technology and Engineering, 2023, 23(29): 12494-12503. [17] 曾慧勇, 陈立峰, 陈亚东, 等. 压裂—驱油一体化工作液研究进展[J]. 油气地质与采收率, 2022, 29(3): 162-170.ZENG Huiyong, CHEN Lifeng, CHEN Yadong, et al. Research progress on fracturing-oil displacement integrated working fluid[J]. Petroleum Geology and Recovery Efficiency, 2022, 29(3): 162-170. [18] 侯向前, 张福祥, 胡广军, 等. 渗吸驱油用表面活性剂研究现状及展望[J]. 化学工程师, 2024, 38(1): 70-74.HOU Xiangqian, ZHANG Fuxiang, HU Guangjun, et al. Research status and prospect of surfacants for imbibition flooding[J]. Chemical Engineer, 2024, 38(1): 70-74. [19] 金智荣, 侯晓蕊, 马巍, 等. 江苏某油田渗吸洗油剂性能评价[J]. 石油化工应用, 2023, 42(4): 28-33.JIN Zhirong, HOU Xiaorui, MA Wei, et al. Performance evaluation of imbibition oil displacement agent in an oilfield in Jiangsu[J]. Petrochemical Industry Application, 2023, 42(4): 28-33. [20] 王科, 卢双舫, 娄毅, 等. 压裂液渗吸与富气页岩气井典型生产规律关系剖析[J]. 特种油气藏, 2024, 31(3): 158-166.WANG Ke, LU Shuangfang, LOU Yi, et al. Analysis of the relationship between fracturing fluid imbibition and typical production rules of gasrich shale gas wells[J]. Special Oil & Gas Reservoirs, 2024, 31(3): 158-166. [21] 朱峰. 中国石化石油勘探开发研究院无锡石油地质研究所实验地质技术之核磁共振岩心分析技术[J]. 石油实验地质, 2023, 45(4): 590. https://www.sysydz.net/article/id/4f34f434-93dd-4dd4-8bda-97f9b91992d3ZHU Feng. Nuclear magnetic resonance core analysis technology of experimental geological techniques of Wuxi Research Institute of Petroleum Geology, SINOPEC Petroleum Exploration and Production Research Institute[J]. Petroleum Geology & Experiment, 2023, 45(4): 590. https://www.sysydz.net/article/id/4f34f434-93dd-4dd4-8bda-97f9b91992d3 [22] 王学武, 杨正明, 李海波, 等. 核磁共振研究低渗透储层孔隙结构方法[J]. 西南石油大学学报(自然科学版), 2010, 32(2): 69-72.WANG Xuewu, YANG Zhengming, LI Haibo, et al. Expermental study on structure of low permeability core with NMR spectra[J]. Journal of Southwest Petroleum University (Science Technology Edition), 2010, 32(2): 69-72. [23] 宁传祥, 姜振学, 苏思远, 等. 泥页岩核磁共振T2谱换算孔隙半径方法[J]. 科学技术与工程, 2016, 16(27): 14-19.NING Chuanxiang, JIANG Zhenxue, SU Siyuan, et al. Method for calculating pore radius distribution in shale reservoirs from NMR T2 spectra[J]. Science Technology and Engineering, 2016, 16(27): 14-19. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号