Issues in shale oil core porosity measurement

-

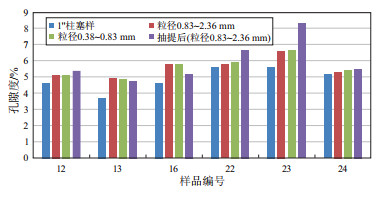

摘要: 页岩孔隙度的测试方法主要分为流体侵入法和电子/射线辐射法两大类。其中,辐射法因存在一定的局限性,目前应用范围不广。由于页岩孔隙结构具有纳米级特征,氦气凭借其分子小、化学性质稳定、渗透性优异,成为测量页岩孔隙度最常用的流体介质。氦气流体在侵入页岩内部时,其渗透效果受样品尺度和孔隙连通性的影响。块状样品因其复杂的孔隙迂曲度而需要较长的压力平衡时间,而颗粒样品能够显著改善页岩纳米孔隙的连通性,探测到更多的孔隙空间,因此所测孔隙度更加真实可靠。为了明确何种粒径具有最佳的样品代表性,并探明在页岩油岩心中复杂的可溶有机质—有机溶剂—纳米孔隙相互作用机制下溶剂抽提对孔隙度的影响,从样品尺度和溶剂抽提两个关键因素出发,系统综述了近年来页岩孔隙度测试方面的进展,并对松辽盆地白垩系青山口组页岩油岩心孔隙度进行了实测分析。研究表明,采用块样视密度和颗粒氦气孔隙度相结合的方法测试页岩油岩心孔隙度效果最佳。建议选用粒径为主体孔径的3~4个数量级的样品,这样既能保证样品的代表性,又能提高实验效率。不建议对页岩油岩心进行溶剂抽提,推荐采用低温真空干燥方法尽可能清除孔隙中含有的可溶有机质,从而提高孔隙度测量的准确性。Abstract: The primary methods for shale porosity measurement are the fluid invasion method and the electron/X-ray radiation methods. Among them, radiation methods, due to certain limitations, are currently not widely applied. Since shale pore structures have nanometer-scale characteristics, helium gas, with its small molecular size, stable chemical properties, and excellent permeability, has become the most commonly used fluid medium for shale porosity measurement. The penetration of helium gas into shale is influenced by core sample size and pore connectivity. Bulk samples require a long time for pressure equilibrium due to their complex pore tortuosity, while grain samples exhibit improved nanopore connectivity in shale with more pore space detected, making the measurement more accurate and reliable. This study aims to determine the sample with the optimal particle size and explore the impact of solvent extraction on porosity under the complex interaction mechanisms of soluble organic matter, organic solvent, and nanopores in shale oil cores. Recent progress in shale porosity measurement is systematically reviewed, focusing on sample size and solvent extraction, and experimental analyses of the shale oil core porosity in the Cretaceous Qingshankou Formation in Songliao Basin are conducted. The research indicates that the combination of bulk sample apparent density with grain helium porosity achieves the best measurement result for shale oil core porosity. It is recommended to use samples with particle sizes that cover 3 to 4 orders of magnitude larger than the main pore diameter to ensure both sample representativeness and experimental efficiency. It isn't recommended to perform solvent extraction on shale oil cores and use low-temperature vacuum drying to remove soluble organic matter in pores, thereby improving the accuracy of porosity measurements.

-

Key words:

- shale oil core /

- porosity /

- sample size /

- solvent extraction /

- pore size distribution

-

表 1 松辽盆地中央坳陷区X井白垩系青山口组页岩基础地球化学特征和矿物组成

Table 1. Basic geochemical characteristics and mineral composition of shale in Cretaceous Qingshankou Formation in well X of central depression zone, Songliao Basin

样品

编号深度/m ω(TOC)/% S1/(mg/g) S2 /(mg/g) Tmax/℃ IH /(mg/g) 矿物组成/% 黏土 石英 长石 方解石 黄铁矿 12 2 339.65 1.14 1.36 5.39 441 473 17.1 33.9 21.4 23.8 3.8 13 2 341.38 1.48 1.66 7.78 441 526 23.1 33.2 9.3 25.5 5.4 16 2 344.10 2.50 1.54 12.49 447 499 23.8 40.4 24.2 8.9 2.7 22 2 360.75 1.64 1.83 7.71 440 470 24.7 33.4 18.7 20.9 2.3 23 2 362.95 2.14 2.28 10.83 446 506 21.3 39.9 20.2 13.7 3.5 24 2 363.93 1.18 1.33 4.62 436 392 24.3 35.8 13.3 22.5 2.3 表 2 松辽盆地中央坳陷区X井页岩样品氦气侵入法孔隙度测试结果

Table 2. Porosity measurement results of shale samples from well X in central depression zone of Songliao Basin using helium invasion method

样品

编号深度/m 视密度/(g/mL) 孔隙度/% 1"柱塞样 粒径0.83~2.36 mm 粒径0.38~0.83 mm 抽提后(粒径0.83~2.36 mm) 12 2 339.65 2.55 4.64 5.14 5.12 5.37 13 2 341.38 2.57 3.75 4.90 4.87 4.78 16 2 344.10 2.48 4.63 5.76 5.77 5.21 22 2 360.75 2.51 5.60 5.79 5.93 6.69 23 2 362.95 2.47 5.59 6.60 6.64 8.31 24 2 363.93 2.55 5.16 5.28 5.44 5.50 -

[1] 翁剑桥, 李夏伟, 戚明辉, 等. 四川盆地龙马溪组页岩孔隙度实验方法分析[J]. 岩矿测试, 2022, 41(4): 598-605.WENG Jianqiao, LI Xiawei, QI Minghui, et al. Study on porosity measurement determination methods of a shale reservoir in the Longmaxi Formation, Sichuan Basin[J]. Rock and Mineral Analysis, 2022, 41(4): 598-605. [2] 崔俊峰, 杨金路, 王民, 等. 基于随机森林算法的泥页岩孔隙度预测[J]. 油气地质与采收率, 2023, 30(6): 13-21.CUI Junfeng, YANG Jinlu, WANG Min, et al. Shale porosity prediction based on random forest algorithm[J]. Petroleum Geology and Recovery Efficiency, 2023, 30(6): 13-21. [3] 欧成华, 王泽宇, 闫博, 等. 湖相页岩油层孔隙度井—震双控建模[J]. 断块油气田, 2024, 31(6): 1021-1030.OU Chenghua, WANG Zeyu, YAN Bo, et al. Well-seismic dual-control modeling of lacustrine shale oil reservoir porosity[J]. Fault-Block Oil & Gas Field, 2024, 31(6): 1021-1030. [4] 代金友, 雷禧桢, 皮莎, 等. 常规压汞—恒速压汞联合曲线构型模式及其指示意义[J]. 新疆石油地质, 2024, 45(6): 735-741.DAI Jinyou, LEI Xizhen, PI Sha, et al. Configuration pattern of combined conventional mercury intrusion-constant rate mercury intrusion curves and its indicative significance[J]. Xinjiang Petroleum Geology, 2024, 45(6): 735-741. [5] 袁龙, 刘文强, 罗少成, 等. 基于声学参数和孔隙结构分类的深层储层饱和度计算方法[J]. 特种油气藏, 2024, 31(3): 61-69.YUAN Long, LIU Wenqiang, LUO Shaocheng, et al. A calculation method of deep tight reservoir saturation based on acoustic parameters and pore structure classification[J]. Special Oil & Gas Reservoirs, 2024, 31(3): 61-69. [6] 吴连波. 页岩核磁共振横向弛豫时间与孔径分布量化关系及应用[J]. 油气地质与采收率, 2024, 31(1): 36-43.WU Lianbo. Quantitative relationship between shale NMR transverse relaxation time and pore size distribution and its application[J]. Petroleum Geology and Recovery Efficiency, 2024, 31(1): 36-43. [7] LIU D, QIU F, LIU N, et al. Pore structure characterization and its significance for gas adsorption in coals: a comprehensive review[J]. Unconventional Resources 2022, 2, 139-157. doi: 10.1016/j.uncres.2022.10.002 [8] 陈宗铭, 唐玄, 梁国栋, 等. 基于深度学习的页岩扫描电镜图像有机质孔隙识别与比较[J]. 地学前缘, 2023, 30(3): 208-220.CHEN Zongming, TANG Xuan, LIANG Guodong, et al. Identification and comparison of organic matter-hosted pores in shale by SEM image analysis: a deep learning-based approach[J]. Earth Science Frontiers, 2023, 30(3): 208-220. [9] 陈可洋, 周辉, 杨微, 等. 散射波波场在裂缝性储集层识别中的应用[J]. 新疆石油地质, 2024, 45(1): 109-117.CHEN Keyang, ZHOU Hui, YANG Wei, et al. Application of scattered wave field in identifying fractured reservoirs[J]. Xinjiang Petroleum Geology, 2024, 45(1): 109-117. [10] YUAN Yujie, REZAEE R. Comparative porosity and pore structure assessment in shales: measurement techniques, influencing factors and implications for reservoir characterization[J]. Energies, 2019, 12(11): 2094. [11] 付永红, 蒋裕强, 陈虎, 等. 页岩柱塞样与碎样孔隙度差异性分析与启示[J]. 石油实验地质, 2020, 42(2): 302-310. doi: 10.11781/sysydz202002302FU Yonghong, JIANG Yuqiang, CHEN Hu, et al. Analysis and enlightenment of porosity differences between shale plug samples and crushed samples[J]. Petroleum Geology & Experiment, 2020, 42(2): 302-310. doi: 10.11781/sysydz202002302 [12] COMISKY J T, NEWSHAM K E, RUSHING J A, et al. A comparative study of capillary-pressure-based empirical models for estimating absolute permeability in tight gas sands[C]//Paper Presented at the SPE Annual Technical Conference and Exhibition. Anaheim, CA, USA: SPE, 2007: 11-14. [13] 李新, 刘鹏, 罗燕颖, 等. 页岩气储层岩心孔隙度测量影响因素分析[J]. 地球物理学进展, 2015, 30(5): 2181-2187.LI Xin, LIU Peng, LUO Yanying, et al. Analysis of influencing factors on porosity measurement of shale gas reservoir core[J]. Progress in Geophysics, 2015, 30(5): 2181-2187. [14] 付永红, 蒋裕强, 夏国勇, 等. 海相页岩孔隙度GRI测定方法优化[J]. 天然气工业, 2020, 40(10): 20-28.FU Yonghong, JIANG Yuqiang, XIA Guoyong, et al. Optimization of GRI porosity determination method for marine shale[J]. Natural Gas Industry, 2020, 40(10): 20-28. [15] MA Binyu, HU Qinhong, YANG Shengyu, et al. Multiple approaches to quantifying the effective porosity of lacustrine shale oil reservoirs in Bohai Bay Basin, East China[J]. Geofluids, 2020, 2020(1): 8856620. [16] BUSCH A, SCHWEINAR K, KAMPMAN N, et al. Determining the porosity of mudrocks using methodological pluralism[M]// RUTTER E H, MECKLENBURGH J, TAYLOR K. Geomechanical and Petrophysical Properties of Mudrocks. London: Geological Society of London, 2017, 454: 15-38. [17] LUFFEL D L, GUIDRY F K. New core analysis methods for measuring reservoir rock properties of Devonian shale[J]. Journal of Petroleum Technology, 1992, 44(11): 1184-1190. doi: 10.2118/20571-PA [18] ZHAO Chen, ZHOU W, HU Qinhong, et al. Porosity measurement of granular rock samples by modified bulk density analyses with particle envelopment[J]. Marine and Petroleum Geology, 2021, 133: 105273. doi: 10.1016/j.marpetgeo.2021.105273 [19] WANG Qiming, HU Qinhong, ZHAO Chen, et al. Sample size effects on petrophysical characterization and fluid-to-pore accessibility of natural rocks[J]. Nanomaterials, 2023, 13(10): 1651. doi: 10.3390/nano13101651 [20] DAVUDOV D, MOGHANLOO R G. Upscaling of pore connectivity results from lab-scale to well-scale for Barnett and Haynesville shale plays[C]//Paper Presented at the SPE Annual Technical Conference and Exhibition. Dubai: SPE, 2016. [21] GAUS G, KALMYKOV A, KROOSS B M, et al. Experimental investigation of the dependence of accessible porosity and methane sorption capacity of carbonaceous shales on particle size[J]. Geofluids, 2020, 2020(1): 2382153. [22] PENG Sheng, LOUCKS B. Permeability measurements in mudrocks using gas-expansion methods on plug and crushed-rock samples[J]. Marine and Petroleum Geology, 2016, 73: 299-310. [23] FU Yonghong, JIANG Yuqiang, WANG Zhanlei, et al. Non-connected pores of the Longmaxi shale in southern Sichuan Basin of China[J]. Marine and Petroleum Geology, 2019, 110: 420-433. [24] 杨巍, 薛莲花, 唐俊, 等. 页岩孔隙度测量实验方法分析与评价[J]. 沉积学报, 2015, 33(6): 1258-1264.YANG Wei, XUE Lianhua, TANG Jun, et al. Analysis and evaluation of different measuring methods for shale porosity[J]. Acta Sedimentologica Sinica, 2015, 33(6): 1258-1264. [25] LATIEF F D E. Identification and isolation of closed pore in porous rock using digital rock physics approach[J]. AIP Conference Proceedings, 2015, 1677(1): 060012. [26] THOMSON P R, AITUAR-ZHAKUPOVA A, HIER-MAJUMDER S. Image segmentation and analysis of pore network geometry in two natural sandstones[J]. Frontiers in Earth Science, 2018, 6: 58. [27] DARȽAK B, KOWALSKA-WȽODARCZYK M, SUCH P. Methodological aspects of porosity and pore space measurements in shale rocks[J]. Instytut Nafty i Gazu - Państwowy Instytut Badawczy, 2011, 67(5): 326-330. [28] LUFFEL D L, HOPKINS C W, SCHETTLER JR P D. Matrix permeability measurement of gas productive shales[C]//Paper presented at the SPE Annual Technical Conference and Exhibition. Houston, Texas: SPE, 1993: SPE26633. [29] YU Yuxi, LUO Xiaorong, WANG Zongxiu, et al. A new correction method for mercury injection capillary pressure (MICP) to characterize the pore structure of shale[J]. Journal of Natural Gas Science and Engineering, 2019, 68: 102896. [30] LÖHR S C, BARUCH E T, HALL P A, et al. Is organic pore development in gas shales influenced by the primary porosity and structure of thermally immature organic matter?[J]. Organic Geochemistry, 2015, 87: 119-132. [31] HAN Hui, GUO Chen, ZHONG Ningning, et al. Pore structure evolution of lacustrine shales containing type Ⅰ organic matter from the Upper Cretaceous Qingshankou Formation, Songliao Basin, China: a study of artificial samples from hydrous pyrolysis experiments[J]. Marine and Petroleum Geology, 2019, 104: 375-388. [32] VALENZA Ⅱ J J, DRENZEK N, MARQUES F, et al. Geochemical controls on shale microstructure[J]. Geology, 2013, 41(5): 611-614. [33] ZHU Xiaojun, CAI Jingong, LIU Qing, et al. Thresholds of petroleum content and pore diameter for petroleum mobility in shale[J]. AAPG Bulletin, 2019, 103(3): 605-617. [34] MOHNHOFF D, LITTKE R, KROOSS B M, et al. Flow-through extraction of oil and gas shales under controlled stress using organic solvents: implications for organic matter-related porosity and permeability changes with thermal maturity[J]. International Journal of Coal Geology, 2016, 157: 84-99. [35] WEI Lin, MASTALERZ M, SCHIMMELMANN A, et al. Influence of Soxhlet-extractable bitumen and oil on porosity in thermally maturing organic-rich shales[J]. International Journal of Coal Geology, 2014, 132: 38-50. [36] 胡世旺, 张赛, 汪振毅. 考虑多层吸附诱导流的页岩微纳米孔道渗流分形模型[J]. 特种油气藏, 2023, 30(1): 139-146.HU Shiwang, ZHANG Sai, WANG Zhenyi. Fractal model of micro-nano pore seepage in shale considering the multi-layer adsorption induced flow[J]. Special Oil & Gas Reservoirs, 2023, 30(1): 139-146. [37] 侯玉松, 胡晓农, 吴吉春. 不同胶结度的多孔介质中溶质横向弥散的孔隙尺度模拟研究[J]. 地学前缘, 2024, 31(3): 59-67.HOU Yusong, HU Xiaonong, WU Jichun. Pore scale simulation study of transverse dispersion of solute in porous media with different cementation degrees[J]. Earth Science Frontiers, 2024, 31(3): 59-67. [38] LI Wei, STEVENS L A, MEREDITH W, et al. The effect of oil extraction on porosity and methane adsorption for dry and moisture-equilibrated shales[J]. Fuel, 2022, 316: 123304. [39] KUILA U, MCCARTY D K, DERKOWSKI A, et al. Nano-scale texture and porosity of organic matter and clay minerals in organic-rich mudrocks[J]. Fuel, 2014, 135: 359-373. [40] DISTEFANO V H, MCFARLANE J, STACK A G, et al. Solvent-pore interactions in the Eagle Ford shale formation[J]. Fuel, 2019, 238: 298-311. [41] CAO Yan, HAN Hui, LIU Houwu, et al. Influence of solvents on pore structure and methane adsorption capacity of lacustrine shales: an example from a Chang 7 shale sample in the Ordos Basin, China[J]. Journal of Petroleum Science and Engineering, 2019, 178: 419-428. [42] QI Yu, JU Yiwen, CAI Jianchao, et al. The effects of solvent extraction on nanoporosity of marine-continental coal and mudstone[J]. Fuel, 2019, 235: 72-84. [43] DISTEFANO V H, MCFARLANE J, ANOVITZ L M, et al. Extraction of organic compounds from representative shales and the effect on porosity[J]. Journal of Natural Gas Science and Engineering, 2016, 35: 646-660. [44] 王志昊, 赵建华, 蒲秀刚, 等. 页岩油岩心样品洗油实验效率对比分析[J]. 现代地质, 2022, 36(5): 1304-1312.WANG Zhihao, ZHAO Jianhua, PU Xiugang, et al. Comparison of washing oil experiment of core samples from shale oil reservoir[J]. Geoscience, 2022, 36(5): 1304-1312. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号