Quantitative evaluation of brittleness of deep shale gas reservoirs of Wufeng- Longmaxi formations in Lintanchang area, southeastern Sichuan Basin

-

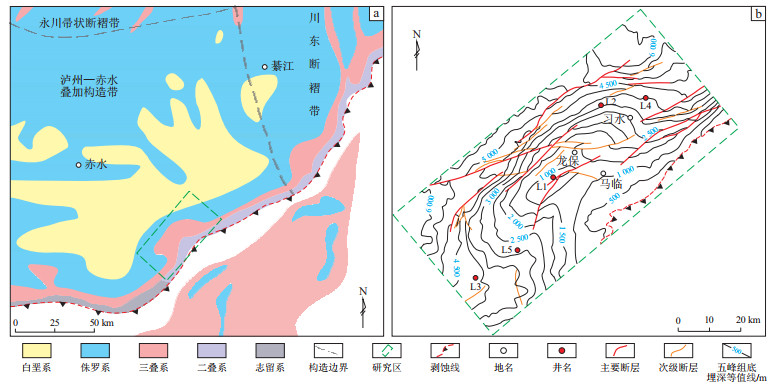

摘要: 随着深层页岩气储层岩石塑性的增加,其脆性特征难以通过传统评价方法进行准确表征。以川东南林滩场上奥陶统五峰组—下志留统龙马溪组一段深层页岩气储层为例,开展页岩样品的三轴岩石力学实验和断裂韧性实验,再结合深度学习对储层脆性进行综合定量评价。岩石力学实验和断裂韧性实验结果表明,随温度和压力的升高,页岩样品杨氏模量、泊松比和抗压强度均有所增加;①号层样品的脆性明显低于③号层样品;脆性较好的页岩样品应力—应变曲线波动特征明显,表现出非线性变形特征,残余应变值较小;页岩样品的断裂韧度与脆性矿物含量关系较为密切,纹层垂直于页理方向的样品Ⅰ型和Ⅱ型断裂韧度值较低。在考虑页岩物质组分特征、三轴岩石力学特征和断裂韧性特征的前提下,以脆性指数Bel和Bmine3、断裂韧性指数IKIC为数据基础,建立深度学习权重分析模型,累积风险值小于5,模型可靠性较强。根据模型建立综合脆性指数B,与岩心脆性测定值BS的相关性得到显著提高(R=0.852 7)。脆性定量评价结果对深层页岩储层纵向剖面的脆性特征进行了真实反映,研究区五峰组—龙一段③号层底部和②号层储层脆性较好,断裂韧性指数较小,为后期勘探开发的优选目的层。Abstract: With the increase in rock plasticity of deep shale gas reservoirs, their brittleness characteristics become difficult to be accurately characterized using traditional evaluation methods. Taking the deep shale gas reservoirs from the upper Ordovician Wufeng Formation to the first member of Lower Silurian Longmaxi Formation in the Lintanchang area of the southeastern Sichuan Basin as a case study, triaxial rock mechanics and fracture toughness experiments on shale samples were conducted. Based on the experimental results, a comprehensive quantitative evaluation of reservoir brittleness was carried out using deep learning. The experimental results showed that with the increasing temperature and pressure, the Young's modulus, Poisson's ratio, and compressive strength of the shale samples all increased. The brittleness of shale samples from layer ① was significantly lower than that of samples from layer ③. Shale samples with better brittleness exhibited obvious fluctuations in the stress-strain curves, showed nonlinear deformation characteristics, and had relatively small residual strain values. The fracture toughness of shale samples was closely related to the content of brittle minerals, and the fracture toughness values of type Ⅰ and type Ⅱ samples with laminations perpendicular to bedding planes were relatively lower. Based on the shale characteristics of mineral composition, triaxial rock mechanics, and fracture toughness, a deep learning weight analysis model was developed using brittleness indices Bel and Bmine3 and fracture toughness index IKIC as data inputs.The cumulative risk value was less than 5, indicating the high reliability of the model.A comprehensive brittleness index B was established based on the model, and its correlation with the measured brittleness index BS of core samples was significantly improved (R=0.852 7). The quantitative brittleness evaluation results truly reflect the vertical profile of brittleness characteristics in deep shale reservoirs. The reservoirs at layer ③ bottom and layer ② in the Wufeng-Longmaxi formations of the study area exhibit relatively better brittleness and lower fracture toughness index, making them preferred target layers for future exploration and development.

-

图 2 四川盆地东南林滩场地区五峰组—龙马溪组一段深层页岩样品不同温压下的应力—应变曲线

a.第一组,L3井龙一段③号层,4 120.70 m;b.第五组,L3井龙一段①号层,4 134.45 m。

Figure 2. Stress-strain curves of deep shale samples under different temperatures and pressures from Wufeng Formation to the first member of Longmaxi Formation in Lintanchang area, southeastern Sichuan Basin

表 1 四川盆地东南林滩场地区L3井页岩样品三轴岩石力学实验结果

Table 1. Experimental results of triaxial rock mechanics of shale samples from well L3 in Lintanchang area, southeastern Sichuan Basin

样品号 小层 深度/m 岩性 石英+长石/% 碳酸盐矿物/% 黏土矿物/% 围压/MPa 温度/℃ 抗压强度/MPa 杨氏模量/MPa 泊松比 L3-4 ③ 4 120.70 黑色硅质页岩 53.5 14.8 30.6 15 30 150.42 32.97 0.189 L3-5 ③ 4 120.70 30 60 187.16 33.03 0.229 L3-6 ③ 4 120.70 50 90 219.26 36.05 0.241 L3-7 ③ 4 122.76 黑色硅质页岩 52.5 12.6 17.7 15 30 163.59 29.54 0.218 L3-8 ③ 4 122.76 30 60 186.89 31.19 0.235 L3-9 ③ 4 122.76 50 90 230.98 32.78 0.251 L3-16 ② 4 127.50 黑色硅质页岩 52.5 10.8 18.8 15 30 236.67 30.94 0.213 L3-17 ② 4 127.50 30 60 288.84 31.08 0.231 L3-18 ② 4 127.50 50 90 339.94 31.83 0.269 L3-13 ① 4 132.00 灰黑色含钙硅质页岩 36.2 30.6 30.4 15 30 261.51 31.36 0.209 L3-14 ① 4 132.00 30 60 281.96 32.73 0.234 L3-15 ① 4 132.00 50 90 387.65 34.43 0.237 L3-19 ① 4 134.45 灰黑色含钙硅质页岩 35.9 24.9 36.1 15 30 192.86 30.70 0.214 L3-20 ① 4 134.45 30 60 255.53 35.76 0.251 L3-21 ① 4 134.45 50 90 316.96 38.71 0.282 表 2 四川盆地东南林滩场地区龙马溪组深层页岩样品断裂韧性实验结果

Table 2. Experimental results of fracture toughness tests on deep shale samples from Longmaxi Formation in Lintanchang area, southeastern Sichuan Basin

井名 深度/m 小层 岩性 石英+长石/% 碳酸盐矿物/% 黏土矿物/% 与页理方向的关系 KⅠ/MPa·m1/2 KⅡ/MPa·m1/2 L2 3 011.00 ③ 黑色硅质页岩 40.9 14.9 36.1 平行 0.145 3 016.58 ④ 黑色硅质页岩 42.4 16.2 29.6 平行 0.369 L3 4 122.76 ③ 黑色硅质页岩 52.5 12.6 17.7 平行 0.241 0.285 4 126.41 ③ 黑色硅质页岩 55.6 13.4 19.9 垂直 0.212 0.243 4 127.30 ② 黑色硅质页岩 50.2 23.9 20.6 垂直 0.412 0.697 4 128.20 ② 黑色硅质页岩 49.5 25.7 18.5 平行 0.538 0.819 L4 3 907.54 ③ 黑色硅质页岩 52.6 15.9 25.9 垂直 0.483 0.612 3 905.31 ③ 黑色硅质页岩 49.3 17.1 23.8 平行 0.584 0.635 3 917.57 ① 灰黑色含钙硅质页岩 40.2 29.5 28.1 垂直 0.526 0.651 3 917.79 ① 灰黑色含钙硅质页岩 36.4 27.6 33.6 平行 0.582 0.705 L5 2 877.49 ③ 黑色硅质页岩 60.2 11.2 14.1 垂直 0.515 0.712 2 878.89 ③ 黑色硅质页岩 64.2 15.6 12.6 平行 0.631 0.841 2 880.76 ② 黑色硅质页岩 51.3 24.4 22.6 垂直 0.566 0.832 2 881.59 ② 黑色硅质页岩 49.1 25.9 18.7 平行 0.728 0.937 注:KⅠ和KⅡ分别代表Ⅰ型断裂韧度和Ⅱ型断裂韧度。 -

[1] WANG Ziyi, CHEN Lei, CHEN Dongxia, et al. Characterization and evaluation of shale lithofacies within the lowermost Longmaxi-Wufeng formation in the southeast Sichuan Basin[J]. Journal of Petroleum Science and Engineering, 2020, 193: 107353. [2] 郝绵柱, 姜振学, 聂舟, 等. 深层页岩储层孔隙连通性发育特征及其控制因素: 以川南地区龙马溪组为例[J]. 断块油气田, 2022, 29(6): 761-768.HAO Mianzhu, JIANG Zhenxue, NIE Zhou, et al. Development characteristics of pore connectivity in deep shale reservoirs and its controlling factors: a case study of Longmaxi Formation in southern Sichuan Basin[J]. Fault-Block Oil & Gas Field, 2022, 29(6): 761-768. [3] 赵圣贤, 夏自强, 刘文平, 等. 四川盆地南部泸203井区五峰组—龙马溪组页岩裂缝特征及形成演化[J]. 油气地质与采收率, 2022, 29(5): 28-38.ZHAO Shengxian, XIA Ziqiang, LIU Wenping, et al. Fracture characteristics and evolution of Wufeng-Longmaxi Formation shale in Lu203 well area in southern Sichuan Basin[J]. Petroleum Geology and Recovery Efficiency, 2022, 29(5): 28-38. [4] 唐建明, 何建华, 魏力民, 等. 川东南林滩场地区五峰组—龙马溪组页岩气藏压力演化及其地质意义[J]. 石油实验地质, 2023, 45(4): 739-750. doi: 10.11781/sysydz202304739TANG Jianming, HE Jianhua, WEI Limin, et al. Pressure evolution of shale gas reservoirs in Wufeng-Longmaxi formations, Lintanchang area, southeast Sichuan Basin and its geological significance[J]. Petroleum Geology & Experiment, 2023, 45(4): 739-750. doi: 10.11781/sysydz202304739 [5] 葛勋, 郭彤楼, 马永生, 等. 四川盆地东南缘林滩场地区上奥陶统五峰组—龙马溪组页岩气储层甜点预测[J]. 石油与天然气地质, 2022, 43(3): 633-647.GE Xun, GUO Tonglou, MA Yongsheng, et al. Prediction of shale reservoir sweet spots of the Upper Ordovician Wufeng-Longmaxi formations in Lintanchang area, southeastern margin of Sichuan Basin[J]. Oil & Gas Geology, 2022, 43(3): 633-647. [6] 张晨晨, 刘滋, 董大忠, 等. 深层海相页岩脆性特征分析与表征[J]. 新疆石油地质, 2019, 40(5): 555-563.ZHANG Chenchen, LIU Zi, DONG Dazhong, et al. Brittleness analysis and characterization of deep marine shales[J]. Xinjiang Petroleum Geology, 2019, 40(4): 555-563. [7] 侯振坤, 杨春和, 魏翔, 等. 龙马溪组页岩脆性特征试验研究[J]. 煤炭学报, 2016, 41(5): 1188-1196.HOU Zhenkun, YANG Chunhe, WEI Xiang, et al. Experimental study on the brittle characteristics of Longmaxi Formation shale[J]. Journal of China Coal Society, 2016, 41(5): 1188-1196. [8] 李庆辉, 陈勉, 金衍, 等. 页岩气储层岩石力学特性及脆性评价[J]. 石油钻探技术, 2012, 40(4): 17-22.LI Qinghui, CHEN Mian, JIN Yan, et al. Rock mechanical properties and brittleness evaluation of shale gas reservoir[J]. Petroleum Drilling Techniques, 2012, 40(4): 17-22. [9] JARVIE D M, HILL R J, RUBLE T E, et al. Unconventional shale-gas systems: the Mississippian Barnett shale of north-central Texas as one model for thermogenic shale-gas assessment[J]. AAPG Bulletin, 2007, 91(4): 475-499. [10] ZHANG Decheng, RANJITH P G, PERERA M S A. The brittleness indices used in rock mechanics and their application in shale hydraulic fracturing: a review[J]. Journal of Petroleum Science and Engineering, 2016, 143: 158-170. [11] 袁俊亮, 邓金根, 张定宇, 等. 页岩气储层可压裂性评价技术[J]. 石油学报, 2013, 34(3): 523-527.YUAN Junliang, DENG Jin'gen, ZHANG Dingyu, et al. Fracability evaluation of shale-gas reservoirs[J]. Acta Petrolei Sinica, 2013, 34(3): 523-527. [12] 赵金洲, 许文俊, 李勇明, 等. 页岩气储层可压性评价新方法[J]. 天然气地球科学, 2015, 26(6): 1165-1172.ZHAO Jinzhou, XU Wenjun, LI Yongming, et al. A new method for fracability evaluation of shale-gas reservoirs[J]. Natural Gas Geoscience, 2015, 26(6): 1165-1172. [13] 刘致水, 孙赞东. 新型脆性因子及其在泥页岩储集层预测中的应用[J]. 石油勘探与开发, 2015, 42(1): 117-124.LIU Zhishui, SUN Zandong. New brittleness indexes and their application in shale/clay gas reservoir prediction[J]. Petroleum Exploration and Development, 2015, 42(1): 117-124. [14] 何建华, 李勇, 邓虎成, 等. 基于多元力学实验的深层页岩气储层脆性影响因素分析与定量评价[J]. 天然气地球科学, 2022, 33(7): 1102-1116.HE Jianhua, LI Yong, DENG Hucheng, et al. Quantitative evaluation and influencing factors analysis of the brittleness of deep shale reservoir based on multiple rock mechanics experiments[J]. Natural Gas Geoscience, 2022, 33(7): 1102-1116. [15] 徐火龙, 赵迪斐. 深层页岩储层脆性评价及综合脆性指标评价优化路径研究: 以Z-3井五峰组—龙马溪组为例[J]. 非常规油气, 2023, 10(1): 84-92.XU Huolong, ZHAO Difei. Research on brittleness evaluation of deep shale reservoirs and optimization approach of comprehensive brittleness index evaluation: a case study of Wufeng-Longmaxi formation from well Z-3[J]. Unconventional Oil & Gas, 2023, 10(1): 84-92. [16] 孔令运, 宋广朋, 蒋恕, 等. 深层页岩微观力学特征及控制机理: 以涪陵地区平桥区块JYA井深层页岩为例[J]. 石油实验地质, 2024, 46(4): 683-697. doi: 10.11781/sysydz202404683KONG Lingyun, SONG Guangpeng, JIANG Shu, et al. Micromechanical characteristics and controlling mechanism of deep shale: a case study of well JYA in Pingqiao block, Fuling area[J]. Petroleum Geology & Experiment, 2024, 46(4): 683-697. doi: 10.11781/sysydz202404683 [17] 窦亮彬, 杨浩杰, XIAO Yingjian, 等. 页岩储层脆性评价分析及可压裂性定量评价新方法研究[J]. 地球物理学进展, 2021, 36(2): 576-584.DOU Liangbin, YANG Haojie, XIAO Yingjian, et al. Probability study of formation brittleness and new quantitative evaluation of fracability for shale reservoirs[J]. Progress in Geophysics, 2021, 36(2): 576-584. [18] CHEN Hongsong, ZHANG Yongpeng, CAO Yongrui, et al. Security issues and defensive approaches in deep learning frameworks[J]. Tsinghua Science and Technology, 2021, 26(6): 894-905. [19] RADWAN A E, WOOD D A, RADWAN A A. Machine learning and data-driven prediction of pore pressure from geophysical logs: a case study for the Mangahewa gas field, New Zealand[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2022, 14(6): 1799-1809. [20] FENG Shaoke, XIE Runcheng, RADWAN A E, et al. Accurate determination of water saturation in tight sandstone gas reservoirs based on optimized Gaussian process regression[J]. Marine and Petroleum Geology, 2023, 150: 106149. [21] ELHAIJA W A, AL-HAIJA Q A. A novel dataset and lightweight detection system for broken bars induction motors using optimizable neural networks[J]. Intelligent Systems with Applications, 2023, 17: 200167. [22] NEGARA A, ALI S S, AL DHAMEN A, et al. Data-driven brittleness index prediction from elemental spectroscopy and petrophysical properties using support-vector regression[C]//SPWLA 58th Annual Logging Symposium. Oklahoma: SPWLA, 2017. [23] FENG Shaoke, XIE Runcheng, ZHOU Wen, et al. A new method for logging identification of fluid properties in tight sandstone gas reservoirs based on gray correlation weight analysis: a case study of the Middle Jurassic Shaximiao Formation on the eastern slope of the Western Sichuan Depression, China[J]. Interpretation, 2021, 9(4): T1167-T1181. [24] AHMADOV J. Utilizing data-driven models to predict brittleness in Tuscaloosa marine shale: a machine learning approach[C]//SPE Annual Technical Conference and Exhibition. Dubai: SPE, 2021. [25] ORE T M. A machine learning and data-driven prediction and inversion of reservoir brittleness from geophysical logs and seismic signals: a case study in southwest Pennsylvania, central Appalachian Basin[D]. Morgantown: West Virginia University, 2020. [26] ORE T, GAO Dengliang. Supervised machine learning to predict brittleness using well logs and seismic signal attributes: methods and application in an unconventional reservoir[C]//SEG/AAPG/SEPM First International Meeting for Applied Geoscience & Energy. Denver: SEG, 2021: 1566-1570. [27] 卢志远, 何治亮, 余川, 等. 复杂构造区页岩气富集特征: 以四川盆地东南部丁山地区下古生界五峰组—龙马溪组为例[J]. 石油与天然气地质, 2021, 42(1): 86-97.LU Zhiyuan, HE Zhiliang, YU Chuan, et al. Characteristics of shale gas enrichment in tectonically complex regions: a case study of the Wufeng-Longmaxi formations of Lower Paleozoic in southeastern Sichuan Basin[J]. Oil & Gas Geology, 2021, 42(1): 86-97. [28] 管树巍, 梁瀚, 姜华, 等. 四川盆地中部主干走滑断裂带及伴生构造特征与演化[J]. 地学前缘, 2022, 29(6): 252-264.GUAN Shuwei, LIANG Han, JIANG Hua, et al. Characteristics and evolution of the main strike-slip fault belts of the central Sichuan Basin, southwestern China, and associated structures[J]. Earth Science Frontiers, 2022, 29(6): 252-264. [29] WANG Enze, GUO Tonglou, LI Maowen, et al. Exploration potential of different lithofacies of deep marine shale gas systems: insight into organic matter accumulation and pore formation mechanisms[J]. Journal of Natural Gas Science and Engineering, 2022, 102: 104563. [30] 熊亮. 川南威荣页岩气田五峰组—龙马溪组页岩沉积相特征及其意义[J]. 石油实验地质, 2019, 41(3): 326-332.XIONG Liang. Characteristics and significance of sedimentary facies of Wufeng-Longmaxi formation shale in Weirong shale gas field, southern Sichuan Basin[J]. Petroleum Geology & Experiment, 2019, 41(3): 326-332. [31] 郭彤楼, 张汉荣. 四川盆地焦石坝页岩气田形成与富集高产模式[J]. 石油勘探与开发, 2014, 41(1): 28-36.GUO Tonglou, ZHANG Hanrong. Formation and enrichment mode of Jiaoshiba shale gas field, Sichuan Basin[J]. Petroleum Exploration and Development, 2014, 41(1): 28-36. [32] 谢润成, 邓昆, 周国晓, 等. 四川盆地川西坳陷东坡地区下侏罗统大安寨段储层裂缝分布预测[J]. 石油实验地质, 2024, 46(4): 855-867. doi: 10.11781/sysydz202404855 XIE Runcheng, DENG Kun, ZHOU Guoxiao, et al. Prediction of fracture distribution in the Lower Jurassic Da'anzhai Member on the eastern slope of the Western Sichuan Depression, Sichuan Basin[J]. Petroleum Geology & Experiment, 2024, 46(4): 7855-86. doi: 10.11781/sysydz202404855 [33] 黄滔, 李瑞雪, 邓虎成, 等. 四川盆地川西坳陷深部致密砂岩储层地应力场预测及分区评价: 以新场—丰谷地区须家河组二段为例[J]. 石油实验地质, 2024, 46(6): 1198-1214.HUANG Tao, LI Ruixue, DENG Hucheng, et al. Prediction and zoning evaluation of in-situ stress field in deep tight sandstone reservoirs of Western Sichuan Depression, Sichuan Basin: a case study of the second member of Xujiahe Formation in Xinchang and Fenggu area[J]. Petroleum Geology & Experiment, 2024, 46(6): 1198-1214. [34] 陈祖庆, 郭旭升, 李文成, 等. 基于多元回归的页岩脆性指数预测方法研究[J]. 天然气地球科学, 2016, 27(3): 461-469.CHEN Zuqing, GUO Xusheng, LI Wencheng, et al. Study on shale brittleness index prediction based on multivariate regression method[J]. Natural Gas Geoscience, 2016, 27(3): 461-469. [35] 孙川翔, 聂海宽, 苏海琨, 等. 温压耦合作用下四川盆地深层龙马溪组页岩孔渗和岩石力学特征[J]. 石油勘探与开发, 2023, 50(1): 77-88.SUN Chuanxiang, NIE Haikuan, SU Haikun, et al. Porosity, permeability and rock mechanics of Lower Silurian Longmaxi Formation deep shale under temperature-pressure coupling in the Sichuan Basin, SW China[J]. Petroleum Exploration and Development, 2023, 50(1): 77-88. [36] RAHIMZADEH KIVI I, AMERI M, MOLLADAVOODI H. Shale brittleness evaluation based on energy balance analysis of stress-strain curves[J]. Journal of Petroleum Science and Engineering, 2018, 167: 1-19. [37] 张昊天. 海相高成熟页岩储层岩石力学特征及脆性评价技术[D]. 成都: 成都理工大学, 2019: 110-125.ZHANG Haotian. The evaluation technology of rock mechanics and brittleness characteristics for marine high mature shale reservoir[D]. Chengdu: Chengdu University of Technology, 2019: 110-125. [38] HUO Zhipeng, ZHANG Jinchuan, LI Pei, et al. An improved evaluation method for the brittleness index of shale and its application: a case study from the Southern North China Basin[J]. Journal of Natural Gas Science and Engineering, 2018, 59: 47-55. [39] 蒋廷学, 卞晓冰, 王海涛, 等. 深层页岩气水平井体积压裂技术[J]. 天然气工业, 2017, 37(1): 90-96.JIANG Tingxue, BIAN Xiaobing, WANG Haitao, et al. Volume fracturing of deep shale gas horizontal wells[J]. Natural Gas Industry, 2017, 37(1): 90-96. [40] 李庆辉, 李少轩, 刘伟洲. 深层页岩气储层岩石力学特性及对压裂改造的影响[J]. 特种油气藏, 2021, 28(3): 130-138.LI Qinghui, LI Shaoxuan, LIU Weizhou. Rock mechanical properties of deep shale gas reservoirs and their influence on fracturing stimulation[J]. Special Oil & Gas Reservoirs, 2021, 28(3): 130-138. [41] 刁海燕. 泥页岩储层岩石力学特性及脆性评价[J]. 岩石学报, 2013, 29(9): 3300-3306.DIAO Haiyan. Rock mechanical properties and brittleness evaluation of shale reservoir[J]. Acta Petrologica Sinica, 2013, 29(9): 3300-3306. [42] MASRI M, SIBAI M, SHAO J F, et al. Experimental investigation of the effect of temperature on the mechanical behavior of Tournemire shale[J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 70: 185-191. [43] 张军, 艾池, 李玉伟, 等. 基于岩石破坏全过程能量演化的脆性评价指数[J]. 岩石力学与工程学报, 2017, 36(6): 1326-1340.ZHANG Jun, AI Chi, LI Yuwei, et al. Brittleness evaluation index based on energy variation in the whole process of rock failure[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(6): 1326-1340. [44] 陈国庆, 赵聪, 魏涛, 等. 基于全应力—应变曲线及起裂应力的岩石脆性特征评价方法[J]. 岩石力学与工程学报, 2018, 37(1): 51-59.CHEN Guoqing, ZHAO Cong, WEI Tao, et al. Evaluation method of brittle characteristics of rock based on full stress-strain curve and crack initiation stress[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(1): 51-59. [45] 尹帅, 单钰铭, 王哲, 等. Hoek-Brown准则在岩石抗压强度测井解释中的应用[J]. 桂林理工大学学报, 2014, 34(4): 659-665.YIN Shuai, SHAN Yuming, WANG Zhe, et al. Application of Hoek-Brown criterion in rock compressive strength logging interpretation[J]. Journal of Guilin University of Technology, 2014, 34(4): 659-665. [46] 陈勉, 金衍, 张广清. 石油工程岩石力学[M]. 北京: 科学出版社, 2008.CHEN Mian, JIN Yan, ZHANG G Q. Rock mechanics in petroleum engineering[M]. Beijing: Science Press, 2008. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号