CO2 EOR factors in heavy oil reservoirs

-

摘要: 与稀油注CO2提高采收率机理不同,CO2与稠油无法达到混相,因此影响其开发效果的主要因素差别很大,特别是在热化学复合采油过程中,注入的CO2主要发挥隔热、降黏、增能的作用。为了进一步研究不同因素对稠油油藏注CO2驱替效果的影响,在稠油样品物性分析的基础上,利用正交实验方法研究了原油黏度、温度、压力和渗透率对稠油油藏注CO2提高采收率的影响。温度对采收率影响最大,其他因素由大到小依次为:渗透率、压力、油样类型。根据实验结论及认识,综合考虑地层温度、油藏渗透率等因素,在胜利油田开展了稠油油藏注CO2吞吐提高采收率矿场试验。从矿场实际生产结果来看,油藏温度增加以及油藏渗透率提高,都有利于注CO2吞吐开发,都能够有效提高油井产量。Abstract: Different from the mechanism of improving light oil recovery by CO2 injection, heavy oil does not mix with CO2, so the main factors affecting its development are very different. Especially in the process of thermochemical composite oil recovery, the injected CO2 mainly plays a role in insulating heat, reducing viscosity and increasing energy. The properties of heavy oil were determined in this study in order to systematically investigate the effects of different factors influencing CO2 displacement. The effect of heavy oil viscosity, temperature, pressure and permeability on recovery were investigated using the orthogonal experimental method. Temperature was the most significant factor, followed by permeability, pressure and heavy oil viscosity. According to the experimental results and considering factors such as reservoir temperature and permeability, the field tests of CO2 huff and puff in the Shengli Oilfield of SINOPEC were conducted. Production results show that increasing reservoir temperature and permeability is beneficial for CO2 EOR and can improve oil production.

-

Key words:

- heavy oil /

- carbon dioxide /

- orthogonal experiment /

- influencing factors /

- EOR

-

表 1 稠油油藏注CO2提高采收率最佳适用条件的四因素正交实验数据

Table 1. Four-factor orthogonal experiment data for the best conditions for CO2 injection in heavy oil reservoirs to enhance oil recovery

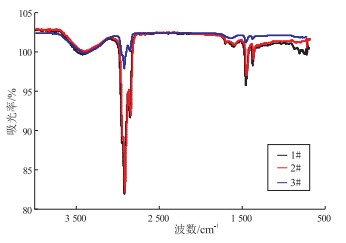

实验 设计的岩心渗透率/(10-3 μm2) 油样 实验温度/℃ 实验压力/MPa 1 250 1# 40 8 2 250 2# 60 12 3 250 3# 80 16 4 500 3# 40 12 5 500 1# 60 16 6 500 2# 80 8 7 1 000 2# 40 16 8 1 000 3# 60 8 9 1 000 1# 80 12 表 2 CO2驱替稠油实验中3种类型稠油黏度与温度的关系

Table 2. Relationship between viscosity and temperature of three types of heavy oil in CO2 flooding experiment

油样 黏度/(mPa·s) 40 ℃ 60 ℃ 80 ℃ 1# 57 500 8 650 1 760 2# 75 200 9 070 1 910 3# 121 000 24 800 4 570 表 3 CO2驱替稠油实验中3种类型稠油四组分分析

Table 3. Four-component analysis of three types of heavy oil in CO2 flooding experiment

油样 四组分含量/% 饱和分 芳香分 胶质和沥青质 1# 20.78 14.05 65.17 2# 24.97 9.22 65.81 3# 17.36 14.97 67.68 表 4 正交实验结果极差分析

Table 4. Range analysis of orthogonal experiment results

实验 渗透率/(10-3 μm2) 温度/℃ 压力/MPa 油样 驱油效率/% 1 257 40 8 1# 8.305 2 231 60 12 2# 9.943 3 234 80 16 3# 26.482 4 502 40 12 3# 6.265 5 500 60 16 1# 13.774 6 490 80 8 2# 36.248 7 959 40 16 2# 6.847 8 977 60 8 3# 17.339 9 936 80 12 1# 39.780 极差 6.412 27.031 4.930 3.925 表 5 正交实验结果方差分析

Table 5. Variance analysis of orthogonal experiment results

因素 偏差平方和 自由度 F比 临界值F(0.10) 渗透率 0.006 2 0.182 3.110 温度 0.119 2 3.606 3.110 压力 0.004 2 0.121 3.110 油样类型 0.003 2 0.091 3.110 误差 0.13 8 注:偏差平方和指一组数据中,各个数与它们的算术平均值之差的平方和;自由度指假设n个数之和的均值为一定值,此时n个数中只有(n-1)个可自由变动,数学上将(n-1)称为自由度;F比指因素水平的改变引起的平均偏差平方和与误差的平均偏差平方和的比值;临界值F(0.1)是指实验的自由度下,信度为0.1时,F比的临界值,F比高于该值,表明实验结果的差异主要是由因素水平的改变所引起的;F比低于该值,表明实验结果的差异主要是由实验误差所引起的。 表 6 稠油油藏注CO2吞吐井相关参数

Table 6. Well parameters of CO2 huff and puff process in heavy oil reservoirs

地层温度/℃ 渗透率/(10-3 μm2) 注CO2前日产油/t 注CO2后日产油/t 增油倍数 年增油/t 井1 59.6 982 1.1 2.2 1.0 229.6 井2 56.0 882 0.8 1.6 1.0 239.4 井3 61.3 455 0.5 1.3 1.6 59.8 井4 62.2 798 0.3 1.1 2.7 173.4 井5 48.8 142 0.6 0.8 0.3 245.0 井6 62.8 358 0.5 1.2 1.4 109.7 井7 51.0 407 2.1 4.1 1.0 600.2 注:增油倍数是指油井注CO2之后的增油量与注CO2前日产油的比值。 -

[1] ISSEVER K, PAMIR A N, TIREK A. Performance of a heavy-oil field under CO2 injection, Bati Raman, turkey[J]. SPE Reservoir Engineering, 1993, 8(4): 256-260. doi: 10.2118/20883-PA [2] 陈举民, 李进, 曹红燕, 等. 浅薄稠油油藏水平井CO2吞吐机理及影响因素[J]. 断块油气田, 2018, 25(4): 515-520. https://www.cnki.com.cn/Article/CJFDTOTAL-DKYT201804023.htmCHEN Jumin, LI Jin, CAO Hongyan, et al. Mechanism and influence factors for CO2 huff and puff of horizontal flooding in shallow and thin heavy oil reservoir[J]. Fault-Block Oil and Gas Field, 2018, 25(4): 515-520. https://www.cnki.com.cn/Article/CJFDTOTAL-DKYT201804023.htm [3] 钱卫明, 曹力元, 胡文东, 等. 我国CO2驱油注采工艺技术现状及下步研究方向[J]. 油气藏评价与开发, 2019, 9(3): 66-72. https://www.cnki.com.cn/Article/CJFDTOTAL-KTDQ201903015.htmQIAN Weiming, CAO Liyuan, HU Wendong, et al. Present situation and further research direction of CO2 flooding injection-production technology and in China[J]. Reservoir Evaluation and Development, 2019, 9(3): 66-72. https://www.cnki.com.cn/Article/CJFDTOTAL-KTDQ201903015.htm [4] 李强, 王彦玲, 李庆超, 等. 压裂用超临界CO2增稠剂制备及增稠性能评价[J]. 断块油气田, 2018, 25(4): 541-544. https://www.cnki.com.cn/Article/CJFDTOTAL-DKYT201804029.htmLI Qiang, WANG Yanling, LI Qingchao, et al. Synthesis and performance evaluation of supercritical CO2 thickener for fracturing[J]. Fault-Block Oil and Gas Field, 2018, 25(4): 541-544. https://www.cnki.com.cn/Article/CJFDTOTAL-DKYT201804029.htm [5] JHA K N N. A laboratory study of heavy oil recovery with carbon dioxide[J]. Journal of Canadian Petroleum Technology, 1986, 25(2): 54-63. [6] 孙而杰, 彭旭, 朱连忠, 等. 注CO2提高普通稠油油藏驱油效率物理模拟试验研究[J]. 实验室科学, 2010, 13(3): 90-93. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKT201003035.htmSUN Erjie, PENG Xu, ZHU Lianzhong, et al. Study on the physical simulation test of injecting CO2 to improve the flooding efficiency of general heavy oil[J]. Laboratory Science, 2010, 13(3): 90-93. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKT201003035.htm [7] 白锋军, 徐骞, 冯星铮. 稠油油藏CO2驱油机理室内模拟研究[J]. 重庆科技学院学报(自然科学版), 2010, 12(2): 77-79. https://www.cnki.com.cn/Article/CJFDTOTAL-CQSG201002024.htmBAI Fengjun, XU Qian, FENG Xingzheng. Lab simulation research of CO2 oil displacement mechanism in heavy oil reservoir[J]. Journal of Chongqing University of Science and Technology (Natural Sciences Edition), 2010, 12(2): 77-79. https://www.cnki.com.cn/Article/CJFDTOTAL-CQSG201002024.htm [8] 罗瑞兰, 程林松, 李春兰, 等. 稠油油藏注CO2吞吐适应性研究[J]. 西安石油大学学报(自然科学版), 2005, 20(1): 43-46. https://www.cnki.com.cn/Article/CJFDTOTAL-XASY200501014.htmLUO Ruilan, CHENG Linsong, LI Chunlan, et al. Research on the adaptability of cyclic CO2 injection for heavy oil reservoir[J]. Journal of Xi'an Shiyou University (Natural Science Edition), 2005, 20(1): 43-46. https://www.cnki.com.cn/Article/CJFDTOTAL-XASY200501014.htm [9] 杨胜来, 李新民, 郎兆新, 等. 稠油注CO2的方式及其驱油效果的室内实验[J]. 石油大学学报(自然科学版), 2001, 25(2): 62-64. https://www.cnki.com.cn/Article/CJFDTOTAL-SYDX200102019.htmYANG Shenglai, LI Xinmin, LANG Zhaoxin, et al. Laboratory evaluation on displacement efficiency of seven schemes of CO2 injection in heavy oil reservoir[J]. Journal of the University of Petroleum, China, 2001, 25(2): 62-64. https://www.cnki.com.cn/Article/CJFDTOTAL-SYDX200102019.htm [10] 罗瑞兰, 程林松. 深层稠油油藏注CO2开采可行性研究: 以辽河油田冷42块稠油油藏为例[J]. 中国海上油气(地质), 2003, 17(5): 312-316. https://www.cnki.com.cn/Article/CJFDTOTAL-ZHSD200305004.htmLUO Ruilan, CHENG Linsong. A feasibility study on exploitation of deep heavy-oil reservoir by CO2 injection[J]. China Offshore Oil and Gas (Geology), 2003, 17(5): 312-316. https://www.cnki.com.cn/Article/CJFDTOTAL-ZHSD200305004.htm [11] 朱战军, 林壬子, 汪双清. 稠油主要族组分对其粘度的影响[J]. 新疆石油地质, 2004, 25(5): 512-513. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200405015.htmZHU Zhanjun, LIN Renzi, WANG Shuangqing. The influence of heavy oil complosition on its viscosity[J]. Xinjiang Petroleum Geology, 2004, 25(5): 512-513. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200405015.htm [12] 陈栋, 李季, 黄燕山, 等. 胶质和沥青质对原油流动性影响的红外光谱研究[J]. 应用化工, 2010, 39(7): 1100-1104. https://www.cnki.com.cn/Article/CJFDTOTAL-SXHG201007044.htmCHEN Dong, LI Ji, HUANG Yanshan, et al. Influence of the colloid and asphaltene on fluidity of the crude oil by IR spectrum[J]. Applied Chemical Industry, 2010, 39(7): 1100-1104. https://www.cnki.com.cn/Article/CJFDTOTAL-SXHG201007044.htm [13] 文萍, 崔敏, 李传, 等. 稠油及其组分结构参数和红外光谱的考察[J]. 石油化工高等学校学报, 2013, 26(4): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-SYHX201304003.htmWEN Ping, CUI Min, LI Chuan, et al. Research on average structure parameter and infrared spectrum analysis in Venezuela heavy oil and its sub-fractions[J]. Journal of Petrochemical Universities, 2013, 26(4): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-SYHX201304003.htm [14] ZHOU Xiang, JIANG Qi, YUAN Qingwang, et al. Determining CO2 diffusion coefficient in heavy oil in bulk phase and in porous media using experimental and mathematical modeling methods[J]. Fuel, 2020, 263: 116205. doi: 10.1016/j.fuel.2019.116205 [15] LÜ Yuling, HAN Jianwei, HE Limin, et al. Flow structure and pressure gradient of extra heavy crude oil solution CO2[J]. Experimental Thermal and Fluid Science, 2019, 104: 229-237. doi: 10.1016/j.expthermflusci.2019.02.022 [16] ZHU Weiyao, MA Qipeng, SONG Zhiyong, et al. The effect of injection pressure on the microscopic migration characteristics by CO2 flooding in heavy oil reservoirs[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2019: 1-10. -

下载:

下载:

苏公网安备32021102000780号

苏公网安备32021102000780号